Recently, the boys at Sparco Rally xD have been in the middle of prepping their rally car for tarmac duty in preparation of the annual Pikes Peak Hill Climb in Pikes Peak, CO. Although it was originally scheduled to run in July, a wildfire broke out, postponing the event which is now tentatively set for August 12.

But this didn’t stop the Rally xD boys from getting their car ready. As I posted previously, they had a rear beam axle failure. Fortunately, not much was damaged and a new beam was put in (after they reinforced the new beam, that is) along with some rear cosmetic work. Other than that, the car is back to normal!

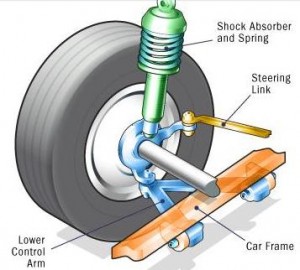

I must say, this car looks plenty tough in this configuration- 18″ Volk TE37’s on a lowered suspension we’ve helped set up specifically for this tarmac event.

More on the event- The Pikes Peak Int’l Hill Climb is in its 90th year. That’s right. People have been crazy enough to race vehicles up the 14,100 ft elevation, all while risking the the potential of falling over the ledge (there isn’t much in the way of barriers, except for some select sections of road) and sent tumbling down since the first World War. This all in a quest to clock the lowest elapsed time up the hill. It’s essentially Time Attack, but on a 13 mile road course and with the aforementioned hazard.

Old timey racing.

New for this year is a completely paved course. In previous runs, it was a mixture of pavement and hard packed dirt. So, as you can imagine, one vehicle setup had to serve dual purpose for these dual road conditions. Not an easy feat. The current record to the top is 9:51:278 in a Suzuki SX4. A Suzuki SX4 that resembles very little of the commuter car we can see on local roads.

This race car sports a 910bhp, turbocharged v6 engine with all that power going to all four tires. And that aero looks like it was jacked straight out of Lockheed Martin’s Skunk Works program, just mounted upside down for road-shoving downforce. So, while it really isn’t a mirror image of an SX4, it’s definitely for the better.

High altitude racing is far from easy. For any of you that have been to areas of high elevation, you probably notice how out of breath you are, even for just a simple walk. Trying to work out in high elevation is even tougher! So imagine a car in which the engine breathes in air to make power does the same thing. Only this time, as the car approaches the 12,000 ft elevation mark, it is down on power by about 30%. This is the effect of elevation- the higher up you go, the less dense the air is. And that lower density air carries less of the power producing oxygen we and our cars need to keep a’moving.

So that explains the big turbocharged horsepower figures. The more air (and fuel) you can force into the engine, the better the chances of it surviving any major loss in power the higher up in altitude it goes.

Good thing the Rally xD is turbocharged, then. It may not be in the 900 bhp mark, but any little bit helps the somewhat tiny 1.8 liter four cylinder.

As always, we hope the Rally xD boys do a great job at this event. By the time you’ve read this, they had already completed the New England Forest Rally (July 13-14), then prep for Pikes Peak again, then back to gravel setup for the Olympus Rally (Sept. 22-23). Daaaaaang, yo! Get some rest somewhere in between all of that, PLEASE!!!

Follow this event at the link below

http://www.usacracing.com/ppihc