As a suspension manufacturer, we’re proud to be able to offer both monotube and twin tube dampers to the market. Both of which offer their own merits in terms of performance.

It is typically viewed that monotube dampers offer the best in performance. They tend to have the most damper oil capacity which reduces damper fade. It also uses a much larger piston which allows us to tune compression and rebound better. It also separates the damper oil from the nitrogen gas charge, eliminating any chance of aeration (mixing of oil and gas, creating bubbles; decreasing damping effectiveness).

In short, monotube dampers sound like the best all-around choice when it comes to performance. However, one area it lacks in is structural rigidity. On strut suspensions, the damper is integral to the knuckle assembly. So that means that the damper must take lateral loads (side forces).

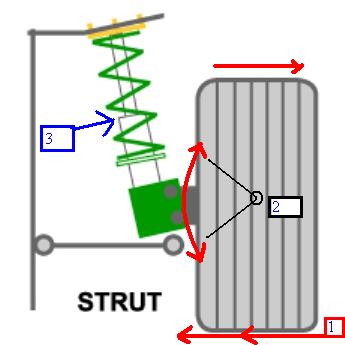

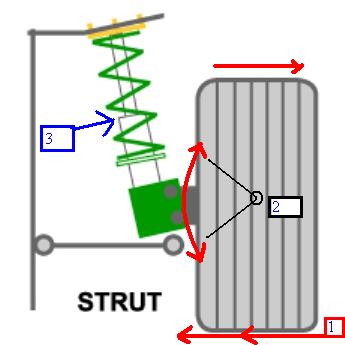

In the drawing above, you can see how this side loading affects the damper. 1) when the tire exhibits lateral loading (in this case, pushing the bottom of the tire towards the center of the car), its tendency is to push the top of the tire outward, away from the car. 2) shows how the wheel/tire assembly wants to rotate due to the added torque from lateral loading. Because of that lateral loading, this places stress on the damper assembly (3).

By our design, we typically make the piston shafts of monotube dampers small in diameter, so that the damper has the highest possible fluid capacity. We could make it much thicker, but then the damper body would probably be much longer since the thicker piston rod, when compressed into the damper, will displace a lot of damper oil (meaning that we’ll need a larger volume for nitrogen gas).

But, to reduce the amount of side load stress on a smaller diameter piston rod for monotube dampers on strut type suspensions, we invert the damper assembly. In doing this, the damper assembly (body containing the oil and gas) sit at the top, and we make the shellcase (strut body) the bottom portion. Essentially, this makes the strut look like it has a massive piston shaft. But, this visually larger diameter can hold up well to the stress of lateral loading. We’ve been able to perfect that design very well, especially in our Group N. rally program.

However, there is always a way to improve. Our new triple tube damper is the latest in strut type monotube technology. No longer do we need to invert the strut. Now, the monotube damper again sits inside the shellcase (lower portion of the damper assembly). However, in between the damper and shell case is another tube. This extra tube can be seen visually (actually looks the same as an inverted strut), and not only protects the damper assembly, but also increases the dampers’ ability to take the lateral loads without adding undue stress and friction under operation.

With this triple tube design, we can now add another guide in which we can distribute lateral loads without affecting the complete damper body’s strength and also reduce friction which can affect damping force.

I took a few pics of a Mono Sport strut damper that our R&D guys were working on

Here you can see the shellcase (black) against the damper (which is covered by the shiny outer tube).

To remove the shiny outer tube from the damper, we remove the insert top (this insert top is what mounts to our pillowball mount, which also holds the damper click knob or EDFC stepping motor). You then have access to the piston rod of the damper.

The shiny outer tube has to be unscrewed from the bottom of the damper. Once removed, you have the complete monotube damper (our engineer reattached the insert top just as reference to show the top of the damper).

From there, it’s pretty much a standard fare monotube damper. However, the new Mono Sport coilovers have new features like Advanced Needle and Advance M.S.V. that separate it from the Mono Flex coilovers. The Advance Needle and Advance M.S.V. provide a broad range in damping force change over the 16 usable click settings, much more noticeable than its predecessor.

These new features stem from improvements we’ve made to our Gr. N dampers with F.R.S. A true testament in TEIN’s research and development in bringing racing technology to the street.

We’re definitely proud to bring the latest technology to the customer. We’re always looking to improve our product. After all, we are TEchnical INnovation!