There seems to be a lot of misunderstandings when it comes to warranties and what we cover as a manufacturer’s defect. So, in case we’ve not yet covered that clearly enough. Let’s just go over some repetitive claims we get.

Now, let me preface this by saying that we’re not claiming to have defect-free products, or that there is no chance our product may prematurely fail. However, we’ve taken extra steps during the manufacturing process of our suspension kits to do our best to ensure the installation and use is problem-free for the end-user.

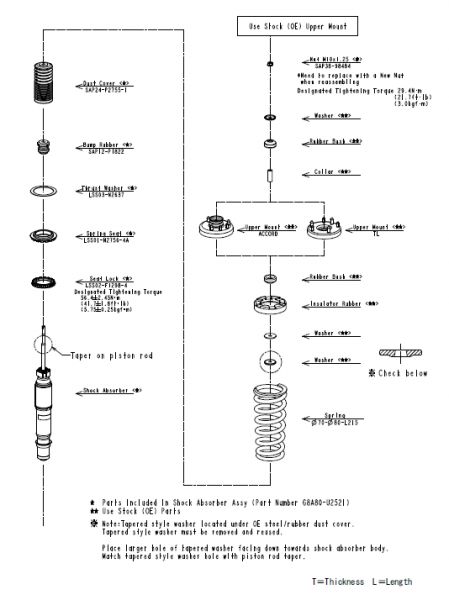

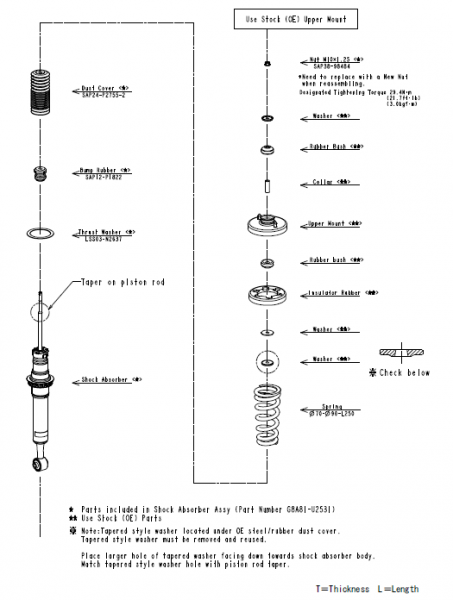

With that said, we seem to run into several issues, especially lately, where our products were not installed correctly, especially with kits that require the use of OEM components like upper mounts. I’ll show an example of a kit that uses OEM upper mount parts on a STREET BASIS Z coilover GSA80-8USS2 (2003-2007 Honda Accord, 2004-2008 Acura TL):

The above pictures are actually from our installation manual for this particular kit. If you notice, we mark some of the items with one star and some with two stars.

One star items are what is included with the coilover kit, while two star items are what are OEM components (not included with the coilover kit).

*The spring isn’t labeled with one star because it’s not part of the part number one star part number if you need to purchase a replacement damper.

But more importantly, these two pictures show the order of parts when installing. Just follow the dotted line from either end until you get to the other end.

Why I’m showing this specific example is because there are a lot of suspensions that use an OEM upper mount of similar design, and quite often we get calls from customers that claim that the piston rod is moving around inside the upper mount, or the piston rod shot so far up that it dented their hood.

Well, that’s because of an installation/assembly error. If the piston rod hit your hood, you’re missing a washer or washers that sit on the piston rod, either sitting on a c-clip or on the tapered end. See the circled washer in both photos? This one shows a slightly blown-up image of it showing which way the tapered hole is to go onto the piston rod.

That tapered hole will sit on the tapered end of the piston rod. In other words, it’s like a wedge fit. And this is important, not simply due to the interference of the two tapers, but because the washer/s allow the upper mount to be securely tightened to the piston rod.

Likewise, components like the collar, and the bushing and washer above the upper mount are just as important. Without the collar, the piston rod will have too much slop inside the mount. without the upper bushing the piston rod can move around and could basically grind itself against the upper mount and break . But without the top washer, the piston rod could potentially come out of the bottom whenever the shock is fully extended downward.

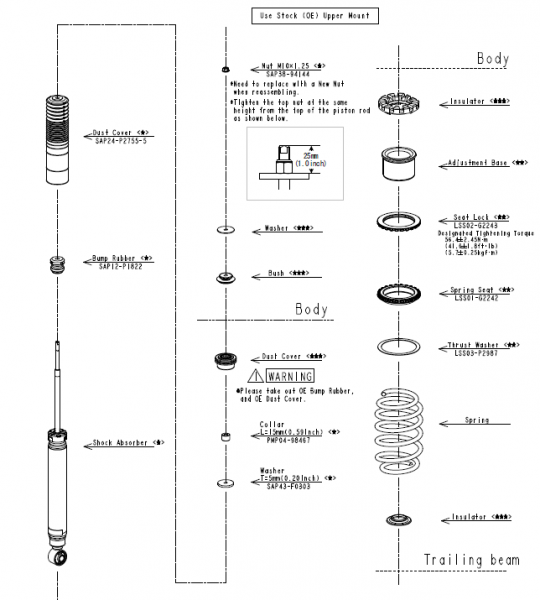

Here’s another example that uses OEM mounts, but for a rear shock that is separate from the spring). This picture is from the customer. They complained of clunking noises at any speed and that they piston rod had noticeable movement even when tightened down. They also supplied a video to show what they were talking about.

The picture obviously doesn’t show the whole mount assembly, but this was what the customer showed as being complete for the under-chassis mount setup.

A look at the installation manual for this customer’s kit shows that the rear shock requires an OEM Dust Cover to be installed, and also notes to remove the OEM Bump Rubber and Dust Cover. The OEM Dust Cover is used in conjunction with our included collar and bump stopper.

Here’s a picture of an aftermarket replacement Dust Cover you can purchase online for the same vehicle as the customer’s. Here, from right to left & bottom to top, it shows the OEM (or OEM style) parts- dust cover, bump stop, metal stopper, rubber insulator, and upper parts- rear suspension support (as the OEM refers to it) and washer. The customer only shows the rubber insulator. So, they’re missing the metal stopper (shown on the bottom left of the photo above).

Without the metal stopper, the shock is relying on the rubber insulator to be held to the shock tower. On droop (extension) that may seem fine. But on compression, it is not enough to hold the piston shaft securely to the shock tower.

But, such concerns are not just limited to OEM upper mount assembling, nor is it unique to just these coilovers. We also have had calls or emails related to coilovers like our FLEX Z line.

Coilovers that utilize pillowball upper mounts for strut type suspension also have some small components. Most notable is a collar that is placed between the upper spring seat and the spherical bearing (pillowball). This collar, about 6mm thick, allows the strut to pivot a few degrees to be able to articulate its motion (camber and caster prevent the strut from being perpendicular to the upper mount), and with front strut suspensions, you’ll need this articulation as you steer as camber and caster change when doing so.

We’ve also received a few calls or emails where a customer states their FLEX Z has a strange grinding noise or popping noise while turning. After getting a bit of information and some pictures from the customers, they show a spring seat sitting right against the pillowball mount, missing this 6mm collar. If you can picture what this does- the strut is now completely perpendicular to the upper mount. But again, the mounting point, as well as the relative camber and caster angle for the upright/knuckle, never have these two components been completely perpendicular. That means that there is an incredible amount of force on the piston rod, basically forcing it in angular motions. That could lead to the piston rod snapping, specifically near where the piston rod is threaded to mount to the upper mount. Not only that. If you’re lucky enough to not have a snapped piston rod, the upper spring seat will be grinding against the pillowball stopper under the mount, which is where the grinding and popping noise comes from.

The coilover picture above may look okay to most, but to us we can tell that a critical component is missing between the upper spring seat and the upper mount. The upper mount is sitting completely perpendicular to the upper spring seat.

But this one, which was the customer’s coilover for the opposing side, has the collar in place, which is why you can see that the mount is free to pivot a few degrees.

You can tell that without this collar (6mm thick), the mount would sit right against the upper spring seat. That’s a no-no, and the upper spring seat will end up grinding against the upper mount whenever you steer.

Of course, many times, the customer will state we didn’t include the collar, or whatever critical component, when they received the kit. We don’t want to say the customer’s wrong, but unfortunately they are- all suspension kits go through a function check and parts check at the factory prior to being packaged up and sent out. For a pillowball strut type mount, it’s a matter of making sure the mount can pivot a few degrees in various directions. We’re very adamant about this step being checked during assembly.

We’re not saying we’re perfect, but we definitely try to be. A suspension purchase is a big investment for a lot of you. We’re not trying to make your purchase and installation difficult. In fact, ultimately we’re trying to make our suspension as easy to install and as affordable an install as possible.

Anyway, we just want you to make sure you see our install manual and read it thoroughly. We completely understand if this is your first time ever taking on a performance suspension install, and we of course will always be within reach to assist you with installation over the phone or by email. Take your time and make sure you do it right.