We’ve recently received several calls or emails from consumers regarding the country of origin for our coilovers. So we wanted to clear up the confusion.

In short, coilovers, and our springs for that matter, are being manufactured in both of our facilities- Japan and China.

It shouldn’t be news by now that we have our own factory in China, and it has been operational for nearly 10 years now. Initially, this factory handled our new-at-the-time ENDURAPRO and ENDURAPRO PLUS shock absorber manufacturing. But within the first few years, we were also able to get our STREET BASIS Z & STREET ADVANCE Z kits made at this factory. It wasn’t that cut and dried of a plan, though. TEIN Japan was still manufacturing a majority of the coilovers. It is just that TEIN China needed to address product manufacturing for their local market and soon demand increased and we found ourselves needing to increase more manufacturing out of this factory to meet global demand.

Then, the pandemic threw all of us a curveball. If anyone can recall, there was a period of incredibly ridiculous costs on freight. Soon, we hit a problem with getting containers and scheduling vessels from our Yokohama facility. From China, however, shipping wasn’t much of a concern. The only exception being regional lockdowns in China due to the fast-spreading virus, as well as some shut downs due to electric power being rationed (kinda strange). Shipping was still more expensive than usual, yes. But at least we were able to have products shipped. But another problem became apparent- not all of our customers want STREET BASIS Z or STREET ADVANCE Z coilovers. Soon our backorder list was growing by the week, but it seemed to revolve around one specific coilover model- FLEX Z.

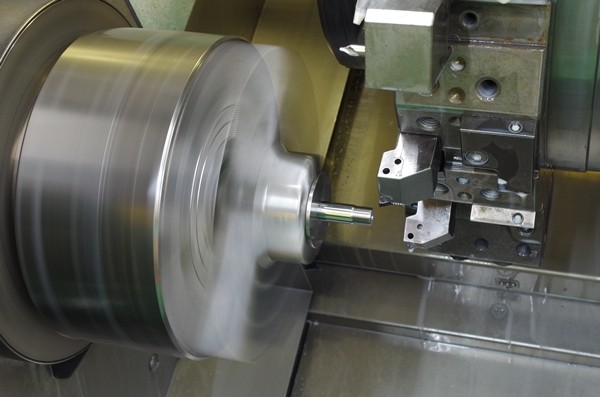

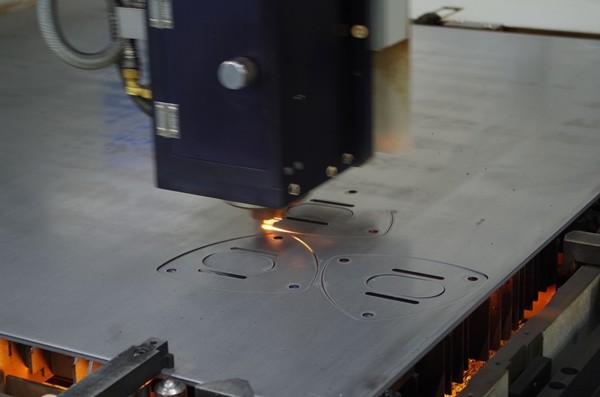

TEIN China had yet to manufacture any of our FLEX coilover line. But the shipping concern forced us to retool for FLEX production out of this facility, and we started adding new machines necessary for FLEX Z production. Starting in late 2021, we received only a few part numbers of FLEX Z from China. But to date, they are now making a majority of FLEX Z kits.

This isn’t to say that TEIN Japan does not manufacture FLEX Z any longer. It’s just that TEIN Japan can now focus on product manufacturing for their domestic market, and a few other Asian countries, as well as for USA.

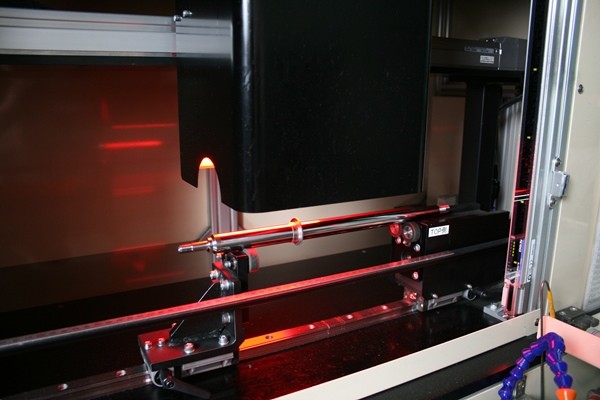

We now have springs being manufactured in China too! This is relatively new, about 1 year or so now. Before, we were having springs shipped to China for the assembly of STREET BASIS Z & STREET ADVANCE Z kits. We were hoping to find a suitable spring manufacturer in China, but several tests of locally manufactured springs didn’t meet our requirements. BUT, by importing coil spring wire from Japan we are now able to have springs made to our specifications. Yes it costs us more to do so, but quality is still paramount to our business. Still, there is a savings in doing so, and ultimately we still want to bring a quality product to our customers, so long as we are in control of that quality.