So we’re a bit late to the party. But better late than never, I suppose. We’ve probably said this many times before.

As Electric Vehicles continue to grow in popularity, and with many nations looking to reduce carbon emissions or become carbon-neutral, it was only a matter of time for the Electric Vehicle market to take off. And it really has taken off.

That’s a great opportunity for aftermarket manufacturers such as TEIN. People may need to rely on their Electric Vehicle strictly for commuting. However, that doesn’t mean they cannot enjoy their car for what it offers at face value. As always, where there’s a vehicle, the performance market is not far behind, and everyone wants that extra bit of performance, whether it be in power or handling, or just to simply have something different or unique.

As many of you have seen by now, the modern Electric Vehicle, namely the Teslas, are quite quick in acceleration. The manufacturer has done pretty well in setting their cars up. But let’s be honest, they’re catering to a global market. You can’t appease each and every person with a “run-of-the-mill” Tesla, regardless of which model Tesla it is.

So, we’re coming out with some performance suspension kits, starting with the Model 3, and soon the Model Y.

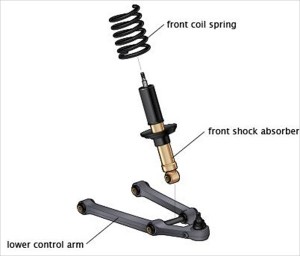

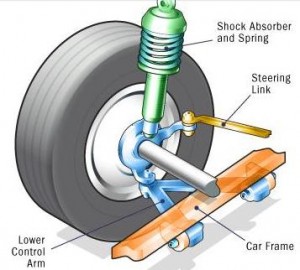

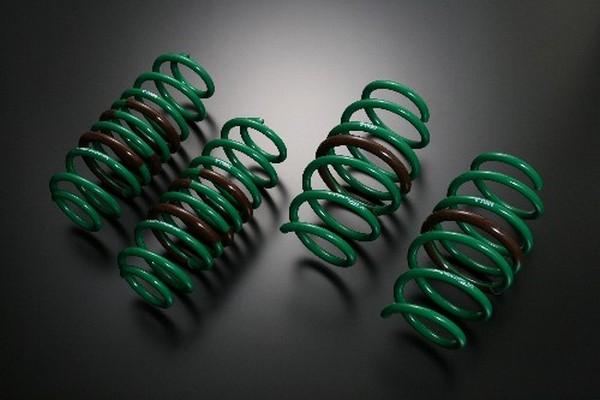

For the Model 3, both rear-wheel drive and all-wheel drive models, we’re making our S.TECH lowering springs, ENDURAPRO and ENDURAPRO PLUS shock absorbers, as well as our FLEX Z coilover kits.

The S.TECH lowering springs will provide a nice lowered ride height without being too aggressive. These will pair well with OEM shocks and struts, but for sure our ENDURAPRO or ENDURAPRO PLUS shocks will be a better pairing.

Part number: SKGP2-AUB00

Ride height drop: Ft- -1.6″; Rr- -1.4″

MSRP: $385

*Sold as a set of 4 springs

Part number: SKGP4-AUB00

Ride height drop: Ft- -1.2″; Rr- -1.4″

MSRP: $385

*Sold as a set of 4 springs

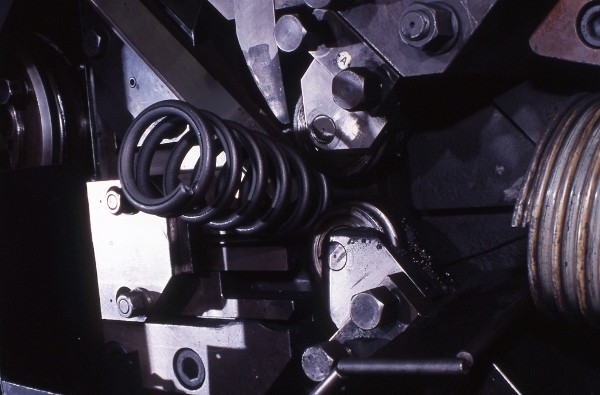

ENDURAPRO and ENDURAPRO PLUS (16-click damping adjustable) shocks are true performance replacement shocks. Damper tuning is optimized to reduce body roll and provide better response to fast inputs. But beyond the tuning, the internal Hydraulic Bump Stopper (HBS) in each shock absorber provide increased comfort and safety by reducing a typical shock absorber’s tendency under full compression (bottoming out) to oscillate. This feature also increases vehicle stability in emergency maneuvers, especially in vehicles with added weight. Also, although designed to be a direct OE fitment, we incorporate a lot of features typical of our coilover kits- larger diameter damper bodies (increased damper oil capacity, larger diameter piston rods, and use of ultra high-strength steel in its construction.

Part number:

ENDURAPRO-

FL- VSGP2-A1MS2-L

FR-VSPG2-A1MS2-R

Rear- VSGP3-A1MS2

ENDURAPRO PLUS-

FL- VSPG2-B1MS2-L

FR- VSGP2-B1MS2-R

Rear- VSGP3-B1MS2

MSRP:

ENDURAPRO-

VSGP2-A1MS2-L – $145

VSPG2-A1MS2-R – $145

VSGP3-A1MS2 – $120

ENDURAPRO PLUS-

VSPG2-B1MS2-L – $160

VSGP2-B1MS2-R – $160

VSGP3-B1MS2 – $135

*sold as individual units

**Model 3 AWD (Dual Motor) shock absorbers coming soon!

Our FLEX Z coilovers, on the other hand, are for consumers who need much more than what our lowering springs and performance shocks can offer. FLEX Z coilovers provided full-length adjustability (separate spring preload and ride height adjustment), 16-way damping adjustment, upper mounts for front and rear dampers, high-rate springs, and valved to provide greater handling performance without compromising ride feel. For sure, much more aggressive for street, but not at the ride quality penalty typically associated with aftermarket coilover kits. Lastly, our FLEX Z coilovers are compatible with our optional Electronic Damping Force Controllers (EDFC)- ACTIVE and ACTIVE PRO, giving you the added benefit of damping adjustment from the driver’s seat. No need to have to manually set your damping by hand, and you can also save up to 10 different presets. However in Active mode, you can have damping that changes based on driving speeds or g-force load. This EDFC setup makes the FLEX Z a true adaptive suspension setup.

Part number: VSGP2-C1AS3

Spring Rates: Ft- 9kg/mm (504lbs/in); Rr- 10kg/mm (560lbs/in)

MSRP: $1,200

*Model 3 AWD (Dual Motor) coilover kit coming soon!

So again, we’re late to the party. We tend to take our time on product development to make sure we get it right, and to make sure we have products that fill the needs of our customers. If you need help deciding on what suspension setup suits you the best, please give us a call at 562-861-9161, or email us at tus_sales@tein.com, and we’d be happy to assist you in getting the suspension you need!

![black friday list page[1]](http://teinusa-blog.com/wp-content/uploads/2013/11/black-friday-list-page1.jpg)

![black friday list page[2]](http://teinusa-blog.com/wp-content/uploads/2013/11/black-friday-list-page2.jpg)