You’ve probably already read our posts about upcoming new products. One, in particular is the new FLEX Z coilover kits which will be here by Spring of this year. We’ve already had a head-start in developing FLEX Z dampers, testing on some of the more popular vehicle applications and working our way down the list, including new vehicles.

You’ve probably already read our posts about upcoming new products. One, in particular is the new FLEX Z coilover kits which will be here by Spring of this year. We’ve already had a head-start in developing FLEX Z dampers, testing on some of the more popular vehicle applications and working our way down the list, including new vehicles.

I’m sure many of you have questions regarding these dampers, wondering what is so different about it and why we probably have to test.

Well, in short, we’re always testing. Just because a new product may be similar to the items they’re superseding doesn’t mean we should simply copy and remanufacture from an older design. Our products are always evolving. We develop products based on customer feedback and work towards making an even better product.

Here are a few FAQ’s:

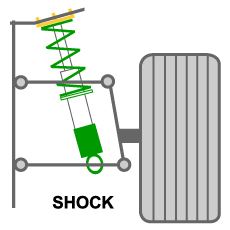

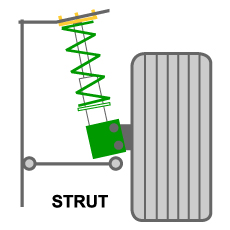

How does this FLEX Z coilover kit differ from the current STREET FLEX?

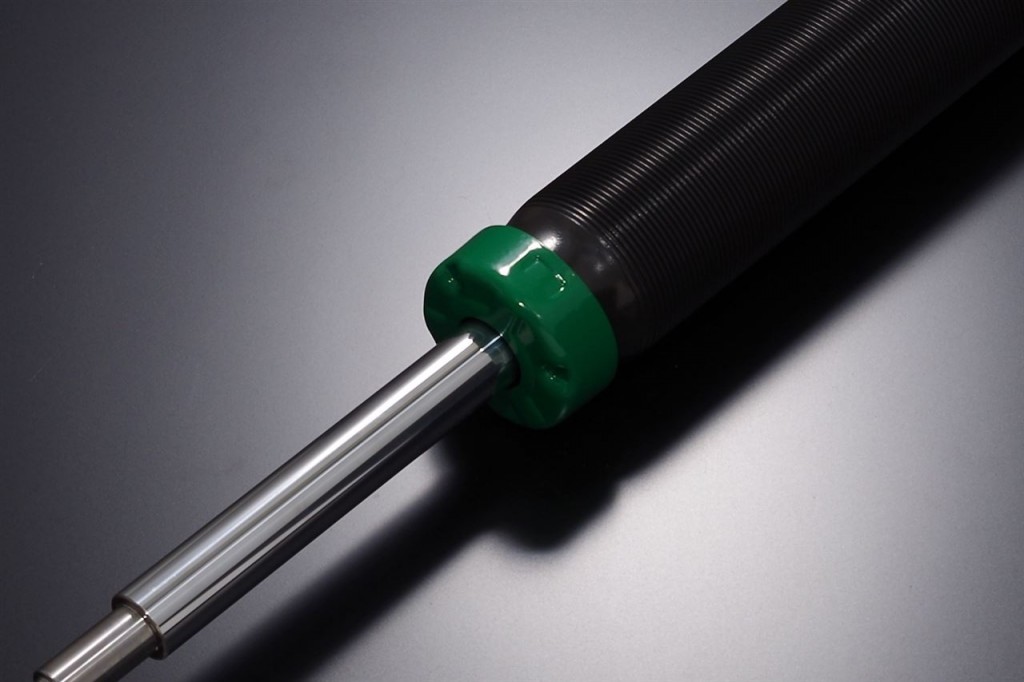

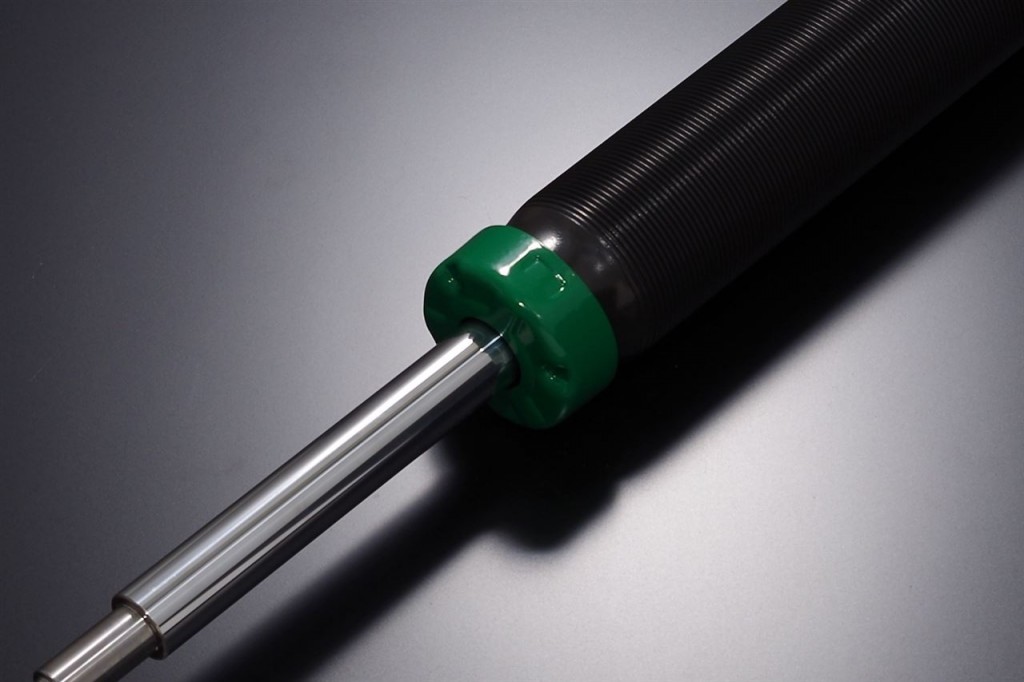

-The only difference is that the new FLEX Z dampers are fully sealed units, rather than the rebuildable setups we make. All other components and features have remained.

Why has TEIN gone with a fully sealed unit?

-The biggest benefit of a fully sealed unit is that we are able to change out a few components that add the the production cost of the coilover kit. We understand that our customers are looking for a more affordable coilover without sacrificing features such as damping force adjustment, height adjustment, and exclusive upper mounts (camber adjustable in some applications).

So, with our fully sealed units, we’re able to cut MSRP down from current iterations of STREET FLEX dampers by nearly $500!!! That’s a massive savings! Starting price for our FLEX Z dampers is $800!!!

Any downsides to a fully sealed unit?

-Obviously that is a great concern for a lot of our customers, especially ones that are already familiar with our overhaul service.

As all of our current coilovers are rebuildable, the customer can send any damper that may have blown a seal, or just needs to be refreshed, and we can do that in-house. We also have the ability to revalve the dampers for different spring rates, should the customer want to match for a specific spring rate in mind. Our engineers have motorsports experience too, so we can work with a customer who has very detailed concerns with damping for specific tracks or driving conditions.

We’re very proud to be able to offer this unique service to our customers, as many suspension manufacturers do not have a damper service option. However, it is not as common a request from our customers. In fact, a majority of the dampers we receive are really for damper revalving and customization, and not just rebuilds. If anything, that serves as a great testament to the durability of our products.

With a fully sealed unit, we cannot open them up again. So, overhaul service will not be available for the FLEX Z line.

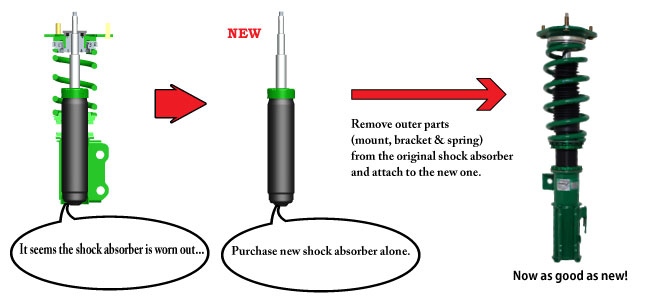

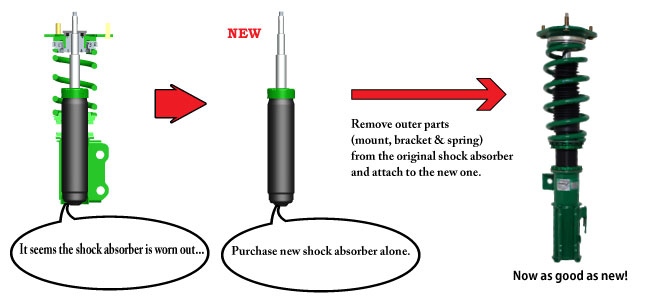

So, what happens if one of my FLEX Z dampers blow out? Can I get a replacement?

-You can absolutely get replacement FLEX Z dampers! Contact us for pricing on individual dampers (damper sub assembly), should you ever need one! While we cannot sell direct to the public, we can at least give you this information and even help you find a nearby authorized TEIN dealer that you can purchase replacement parts from. All we will need from you is the part number and lot number from the damper, which is placed on a silver label on the damper itself (label may be placed on lower bracket).

But I was hoping to be able to get a customized set, one with my own valving. Is that still possible?

-Actually yes, it is still possible! You can special order a custom setup for the FLEX Z dampers. It may take some time, since it is coming from Japan (eta is 3-4 months). Since we cannot open the dampers, it will have to be manufactured with another lot. Time frame is dependent on current order/manufacturing schedule. And yes, this does mean that the FLEX Z, as well as FLEX A, coilovers will continue to be made in TEIN Japan’s Yokohama factory.

In fact, if you already have a FLEX Z coilover kit, but are really considering purchasing a specially valved set of dampers, you can just order those specially valved damper sub assemblies separately. Of course, that means you end up with two sets of damper sub assemblies (one out-of-the-box valving, one custom valved). However, that saves you from having to order a complete coilover kit and essentially means you have a back up set of dampers. Mind you, there is still an average ETA of 3-4 months for the custom valved damper units.

Does this all translate to FLEX Z being an inferior product?

-Not at all! In fact, the quality of our dampers has to be even better if we’re going to make a fully sealed unit. That’s our challenge, but we’re very confident in our technology, and we feel that we can provide the same warranty against any manufacturer’s defects with these new FLEX Z dampers! Should you experience any problems with your dampers within the first year of the purchase, send it in to us along with a copy of your receipt from an authorized TEIN dealer and we can take of replacement parts for you, once our claims department has handled all necessary paperwork and questionnaire.

Is the current STREET FLEX better than the FLEX Z?

That isn’t necessarily the case. What we’ve done here is now offer a product to match a customer’s price point. In fact, all of our products are listed in terms of customer budget, as well as features.

Prior to deciding what coilover you want to use, we typically want to find out more information from the customer:

-What is the kit being used for?

-Is this car mainly a street car, occasional track (how often), track only?

-What kind of tracks do you drive on, and can you describe the course and road surface?

-If you are already experiencing any concerns with your current ride quality, please tell us what they are.

-What suspension features do you need?

-What is your budget for new suspension?

Those are just some of the questions we ask. Again, ultimately it is about how much you can spend to get the features you need.

We’re very proud to bring this new product for 2015, and most of all, we’re excited to receive such great responses from customers, especially knowing that TEIN quality and technology can be had at a much more affordable price!

Got questions? Give our sales staff a call at 562-861-9161 for more information!