One major component for a damper is a piston rod that has to be low friction, but also robust enough to handle stress loads and high temperatures. Typically material-wise, it has to be a high-strength alloy.

In our case, we use cold-drawn chrome-moly steel rods. The cold-drawing method helps to produce a near-finished surface that only needs to be polished (done by centerless grinding). In doing so, the piston rod, which is in contact with several components like our dust seal, some o-rings, and our piston rod guide, which is PTFE (Polytetrafluoroethylene) coated.

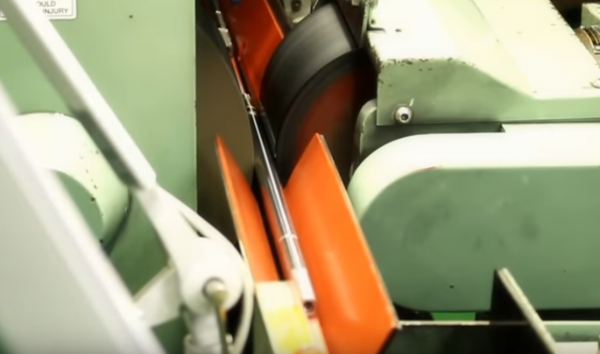

This shows are centerless grinding of piston rods during production.

Over time, especially from high mileage use, this polished piston rod surface can start to see some wear. Debris being kicked up from the road will contact the piston rod surface, scratching and, in more extreme cases, pitting the surface. This can create proud bumps on the piston rod. When portions that are subjected to this scratching/pitting contact other parts of the damper, like the dust seal, it can damage it, allowing dirt and debris to enter the damper.

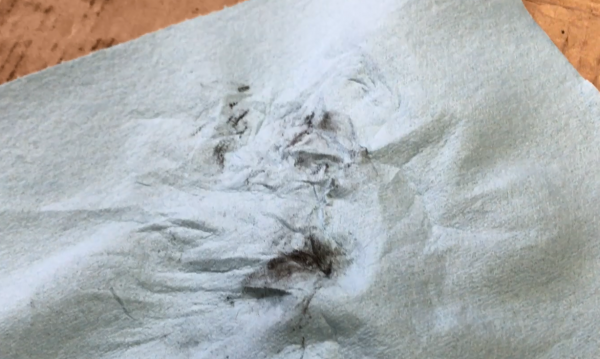

Even such light scratches as shown below can cause problems like noise during operation.

During periodic inspections of your suspension (you are inspecting them, right?), it is a good idea to inspect the piston rod surface, especially portions under the dust boot and at the top of the damper body (where the dust seal is). You may notice that this portion of the piston rod may have a much more finely polished surface compared to other parts of the rod that do not actually enter the damper. At this “working” section, you should inspect for any light scratches or pitting.

In many cases, these scratches/pits can be corrected by polishing using an abrasive compound (we’ve actually used Mother’s Wheel Polish) and a cloth to rub the compound back and forth over the piston rod surface. You’d be surprised how good a finish you can put back onto the piston rod just by polishing by hand.