Hey everyone, just here to give everyone tips on proper maintenance of your TEIN coilovers. Before that I just want to mention a couple Overhaul Customers who may have had a chance to read up on my previous post regarding the packing of dampers being sent in for repairs. Check out the pics below of the creative packing that did not go unnoticed.

Two thumbs up to Jason M. and Marshall J. for the unique and well packed repairs.

_________________________________________________________________________________________

A lot of folks seem to think that overall maintenance is not required for you coilovers but that is wrong. OE shocks and struts may not require maintenance since they do not have adjustable adjustable parts.

Overlooking the maintenance can cause issues with seized parts such as seat locks, lower adjusting brackets, pillowball mount bearing and casing, etc… Even though we use special coatings on various components it is still possible for debris and/or moisture to build up and cause serious damage.

Periodic maintenance of dampers and components can prevent many future issues such as thread damage, seized parts, rusting and blown seals. Regular maintenance will definitely save your high dollar investment and prolong product life.

Routine Maintenance while the units are still on the vehicle:

– Basic wipe down or dirt removal. Can be down with a plastic bristle brush, rags, compressed air, etc…

– Lubrication

Specific areas to clean are the threaded section, upper mounts and lower brackets.

At this time we also suggest a visual inspection of dust boot, mount bushings, spring seats, and bolts/ nuts.

Seasonal or annual major maintenance – with the dampers off the vehicle.

– Full dis-assembly of unit to clean and lube all parts.

– If there is really stubborn debris or damage you can use a wire wheel brush*.

– If rust is found, the rust should be completely removed** and the effected areas repainted.

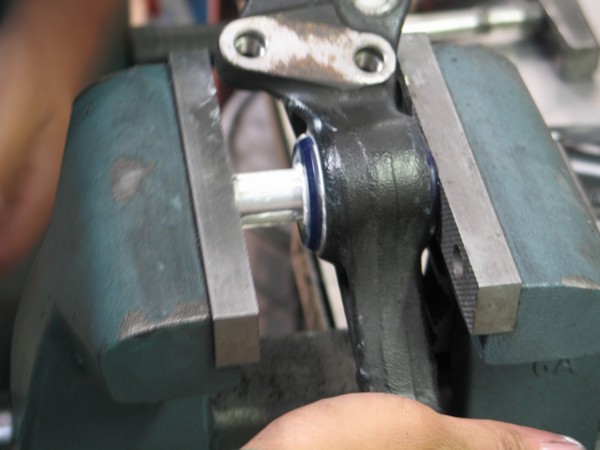

*When using a wire wheel do not put too much pressure as it could brush away the coating which would allow corrosion and rust to form easily. (The picture provided below demonstrate the removal of some oxidation and rust on the threaded sleeve portion. The seat locks should be removed when cleaning all damper conditions).

**Parts cleaner or any heavy duty de-greasers are not recommended as they could eat away at the powder coating, stripping the damper to bare metal, as well as erase the ink print on the stickers and maybe even remove some coating on the threaded body.

Lubrication

Lubrication should be applied to threaded sleeve, seat locks , and other parts.

For lubricant of choice, we use either a light film of Lithium Grease or a Rust Inhibitor.True the grease may attract more debris but it will keep a longer lasting barrier than some Rust Inhibitors. Just be sure to wipe off any overspray or excess grease to avoid any confusion thinking the dampers are leaking oil or build up of debris. For Pillowball Mounts the grease is the best choice as it would help decrease the bearing noise and provide protection against protection.

All in all keeping the dampers clean and lubed will save you from any expensive repairs, down time, and headaches.