In observance of the National holiday, TEIN USA, Inc. operations will be closed from 11/24-11/27 and will resume operations on 11/28.

We hope you all have a safe and wonderful Thanksgiving!

In observance of the National holiday, TEIN USA, Inc. operations will be closed from 11/24-11/27 and will resume operations on 11/28.

We hope you all have a safe and wonderful Thanksgiving!

Hey everyone! Back again with another bit of info regarding our S.Tech and High Tech lowering springs.

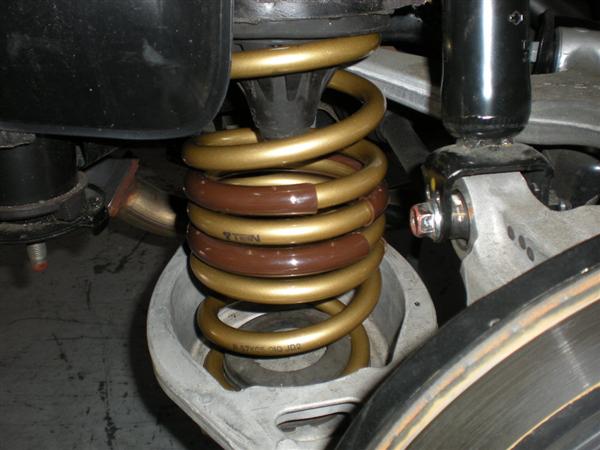

Both spring lines are manufactured with progressive springs rates which would differ from OE springs found on vehicles or any standard springs found on most coilover kits.

Progressive springs usually have two different spring rates – one softer, easily compressible rate and one stiffer or main spring rate.

The softer portion of the spring is actually not felt at all as it is designed with the idea to place a light load on the shock absorber when fully extended. Once load is placed on the spring , the softer portion of the spring fully compresses leaving the main spring rate to support the load. Silencer Rubbers are used in these locations to help in reduce any sounds of coil binding that can be produced during normal operation.

A common misconception about progressive springs is that they will change in rate during operation, gradually becoming stiffer as the springs compresses. Again, the main purpose of the progression is to allow some preload to the shock absorber assembly when fully extended (so that the spring isn’t loose in its mount).

I hope this was able to clairify any questions those may have had regarding TEIN S.Tech or High Tech lowering springs.

Ever wanted to touch up or repaint your dampers because they had some scratches, scuffs, slight rust building on the damper shell casing but couldn’t figure out the a color to match our dampers? Well it’s your lucky day because I’m going to give everyone some tips as well as paint color that would match the TEIN green color.

Because the dampers are powdercoated from TEIN Japan we don’t have the machinery to re-coat them at either of our North American facilities. During Overhaul we do offer to paint them using paint found at your local hardware store. The paint is by Rust-O-Leum Painter’s Touch in Gloss Green Meadow. The color is not exact but closely resembles the original powdercoating as you can see in the second photo down, the left damper being the painted damper and right damper having the original powdercoating.

When repainting or touching up your dampers it is always good to have the dampers clean, free of dirt, debris, and oil. I Recommend staying away from heavy duty parts cleaners as they eat away at the paint as well as the sticker/ label print. Mild cleaners are good, but if heavy duty cleaners are needed, try using a minimal amount.

Preparing the damper may vary from one damper to another, based on its condition. Taping off any sticker/ labels as well as the threaded sleeves,top ring nut, and piston rods is always good as it would help for the future damper reference, as well as the threaded sleeves and top ring nut.

Mild sand paper or, if needed, a wire brush are recommended to allow for larger paint chips and rust to be removed for a clean and even surface. Little surface sanding will allow for a better adhering surface. A bench grinder with a brush wheel could also be used to help with the clean up process of the paint but can be a bit tricky with some hard to reach areas, which is why I can only recommend it to those who know their way around a bench grinder. Wipe down the surface with a lightly damped towel to remove any last foreign debris that may still be on the damper from the prep work.

Before painting, make sure the damper is placed in a good position allowing for easy access to all painting surfaces of the damper. A well ventilated area is always a must. Primer is recommended to allow the paint to adhere.

Even spraying motions back and forth in one direction at a 5 inch distance prevents any uneven coats, as well as overspray drips.

Allow a few hours for the paint to cure. Of course, time frame is longer in humid areas. Check the damper for any areas missed for resprays. Once thoroughly dried your damper is complete.

The same details above can also work with the S.Tech Lowering Springs and Full Length Adjustable Dampers lower adjustment brackets (Flex, and Super Drift) as they are also green. Other dampers and parts may also be green such as spring seat locks, and uppermounts but are anodized instead painted and wouldn’t look good redone in paint.

I hope this helps a few out there looking to repaint or touch up the paint on their dampers.

To some automotive enthusiasts with suspension modifications, many think “install it, set it and forget it”. In many ways, this in incorrect. One thing everyone should consider is that suspension is exposed to the elements of the road. Whether its debris, rain, snow, dirt, mud, sand and possibly road kill, over time these elements could take a toll of the performance and life of any brand suspension. I wanted to go over a few tips for cleaning your suspension that myself and a few other coworkers use.

Cleaners and cleaning tools needed:

Running water, light brush, cleaning solvent in spray bottle (ex. Simple Green), rubbing alcohol, spray lubricant, clean terry cloth and elbow grease.

Damper removed for cleaning

Damper shown fully disassembled for cleaning. The adjustment threads were covered with dirt that made the seat locks hard to remove.

After 10 minutes of cleaning with the brush, simple green and water the damper is looking new again. Once the damper is dry, we clean the piston rod with rubbing alcohol to get rid of any water spots and remaining soap. Before we reassemble, it’s recommended to spray the threads on the damper body and piston rod with a spray lubricant to help from parts becoming seized and rusted.

The damper all assembled again and torque to the recommendations in the installation manual. This damper is ready to rock and roll!

As we have all seen and followed the inflation for Importing Products is quite high at this moment which is forcing us to not be able to have these in stock.

Unfortunately we are hit by the same issues that every company is experiencing at this moment. We will regrettably be holding all SuperPro stocking order but will be ORDERING SuperPro as Special Orders Only. Meaning that we will still be placing orders with SuperPro for all your orders but will take about 4-8 weeks to receive in and all orders have to be paid in advance, and no cancellations.

These bushings are designed to last longer from other manufacturers bushings since these come with double helix,bullet and knurling grooves.

The double helix provides a region for grease to travel along. This allows a boundary layer of grease to form between the inside diameter of the bush and the outside diameter of the tube. The double helix is extremely successful in greaseable shackles as the grease can travel from the center of the bush along the helix and out to the grease grooves in the head of the bush.

Knurling is used on control arm bushes to enable unrestricted pivoting of the polyurethane bush around the crush tube. The knurling has two inherent design advantages. The knurling reduces the surface area of polyurethane in contact with the crush tube. This reduction in surface area results in less frictional forces being developed. The Super Pro knurl bore combined with the integral grease retention lips keeps the lubricating grease intact for the life of the bushing, and eliminates the necessity for periodic re-greasing.

It’s definitely worth the small wait time.

Of course if you do need these in a RUSH we can also offer an Expedited Shipping quote upon request.

Please check out the following link to place any orders or to see their Online Catalog.

http://www.tein.com/products/superpro.html

We have recently become aware of counterfeit items going around. In past years we have known of counterfeit lowering springs being distributed, but have not seen much lately. We received a few emails to our general tech and customer service email address from customers questioning if they should purchase a specific product.

The following two pictures were from a customer who searched “Defi” on Ebay and found these gauges as the cheapest listings (under $25 each).

This is not a product of Defi. The seller did not list all the features and did not provide any other detailed pictures.

The next two pictures were from a customer checking out a RX7 forum and were confused if these were real.

The seller was claiming that these were our TEIN Super Drift Coilovers made for the FC RX7 going for $800.00 brand new.

If you have any questions or concerns about purchasing a product that may or may not be an Authentic TEIN product, feel free to email us at tus_sales@tein.com so we can verify. The safest route of purchasing TEIN products is through any of our authorized dealers from our Dealer List.