That is correct!

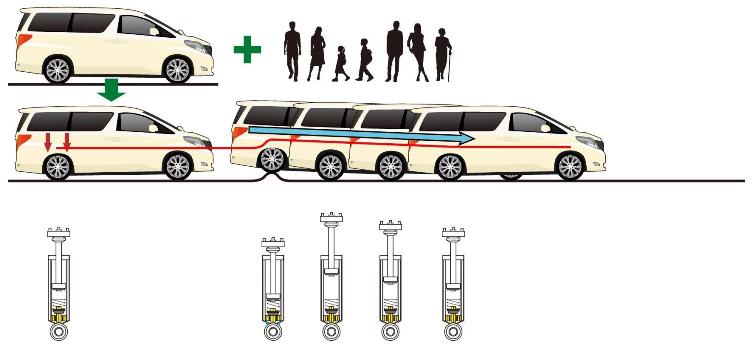

Earlier in 2014, we posted about the new TEIN China manufacturing plant, which construction of the plant was completed before the end of the year. This new plant will be focusing on production of our upcoming line of performance replacement dampers. YES, we will finally be working on replacement dampers designed to work with factory springs, as well as our S.TECH & HIGH TECH lowering spring kits! We’ll blog more on this product later.

However, this will not be the first manufacturing project for TEIN China. We’re going to be receiving our new STREET BASIS Z & STREET ADVANCE Z damper lines from the TEIN China plant.

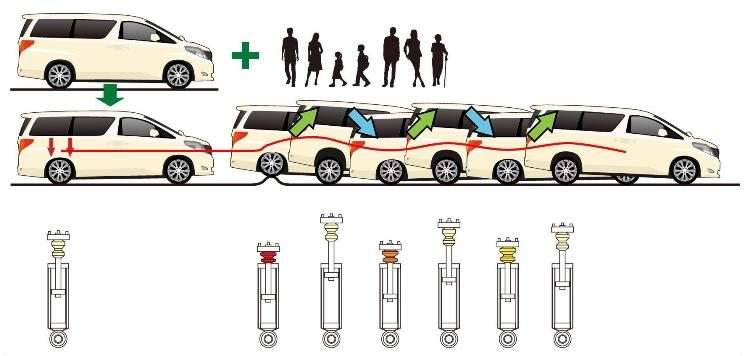

If you had read our previous posts regarding the new “Z” line, you’ll notice that the other Z line of dampers, our FLEX Z coilovers, will be coming from TEIN Japan. Why is that?

It’s a little difficult to explain. But, in short, TEIN is still a very proud Japanese brand. In fact, many of TEIN’s domestic customer base prefer a Japanese manufactured product, especially more of the high-end kits we offer. So TEIN Japan will still continue to produce some of our higher end product lines, such as the upcoming FLEX Z & FLEX A, MONO SPORT, SUPER DRIFT, HG, SUPER RACING, GROUP N., and several other product lines.

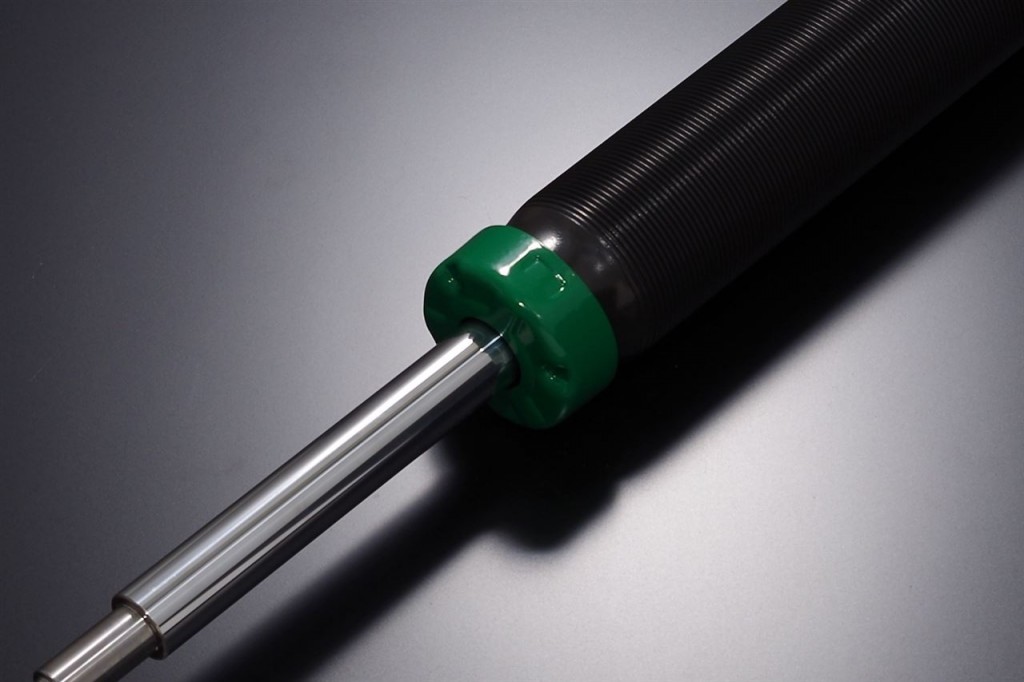

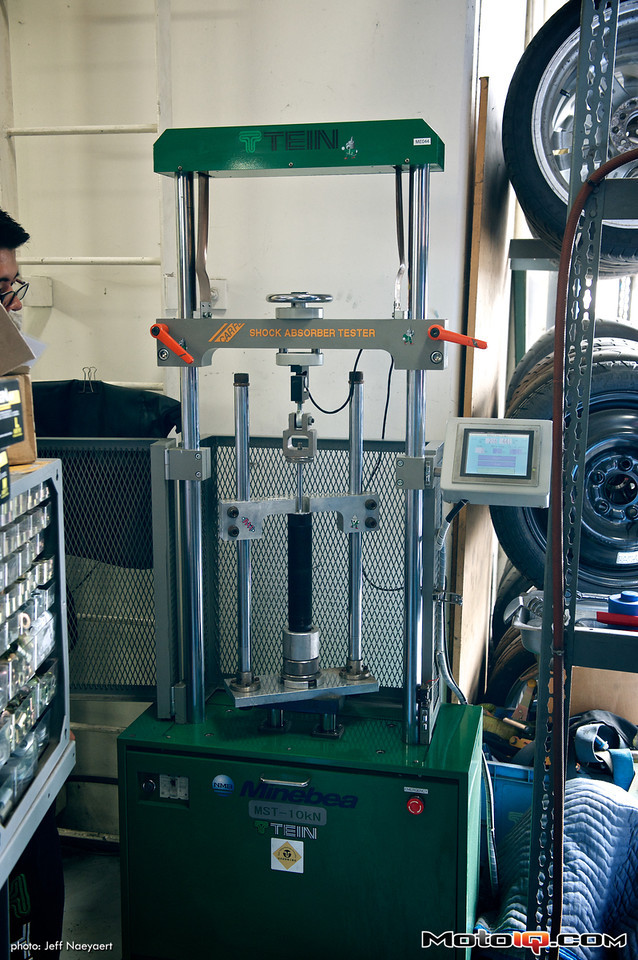

That is not to say there is a lack of pride for the TEIN products coming from the TEIN China plant. In fact, we have invested a lot of money into this new plant in an effort to maintain the same TEIN quality our customers know and expect out of every product. Even machinery and equipment used in TEIN Japan will be the same in the TEIN China plant. A few of TEIN Japan’s engineers and managers will also be making the move to China, not only to train new staff, but to also control all operations. To us, this is a necessary step in controlling and maintaining TEIN quality.

Maybe this would have been a much easier undertaking if we just outsourced manufacturing of these more affordable coilover kits through some other Chinese or Taiwanese manufacturer. Sure, but that isn’t the TEIN way. We’re proud of our technology. Again, we’re not claiming to have invented dampers. We’re just proud to make suspension better through our own engineering and through our own technology.

Still though, why the new factory in China?

A very good question. For several years now, we’ve faced stiff competition in the market place, especially with a lot of these somewhat engineered suspension kits selling for well under $1000. We’re not trying to defame any particular brand. So in their best interests, we’ll leave that information out. Sorry! We’re not here to bash on anyone!

It hasn’t been easy for us. For years, most of the feedback from our authorized dealers and wholesalers is how TEIN suspension is overpriced, and no matter how we dissected our manufacturing process in trying to reduce cost, it still didn’t gain the appeal for a broader range of customers. We were essentially becoming a boutique brand. We’re hoping that opening a new overseas facility helps to address this matter. Of course, this exploits a certain factor about manufacturing in China- affordable labor. However, we’re not in China to simply abuse this factor and gain in profitability. It is just a simple fact about the country and its economic structure, and this is how other manufacturers are able to price their products well below ours. This new affordability in manufacturing translates directly into a more affordable product for our customers.

It wasn’t an easy decision. In fact, it was an idea that we never knew would come to fruition. We didn’t simply decide to open up a new plant. We’re talking about a problem that hadn’t been addressed since late 2008, during the dreaded global financial crisis. Again, we could have simply outsourced manufacturing. But, fortunately, we were able to hang on and maintain some profitability over the next few years in an uneasy industry. We had to outweigh every factor before we made this decision to grow. Now, it’s set in stone, and the TEIN China plant is just about fully operational.

Many of TEIN USA’s staff share the same regards as all other U.S. consumers when we hear “Made in China”. It clearly doesn’t have the appeal that “Made in Japan” does. Typically, we view Chinese manufactured goods as essentially NOT GOOD. That was just something most of us grew up hearing and reading about. It’s sad. Then again, think about how many other goods come from China… Why is it that China is commonly associated with terrible quality? I think this is something that TEIN plans to dispel. Being that we’re in control of all aspects of this manufacturing plant, we have the opportunity to change that “Made in China” label. We think that, naturally, Chinese manufacturing can improve.

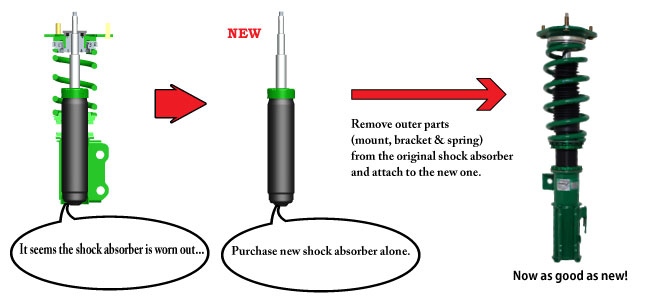

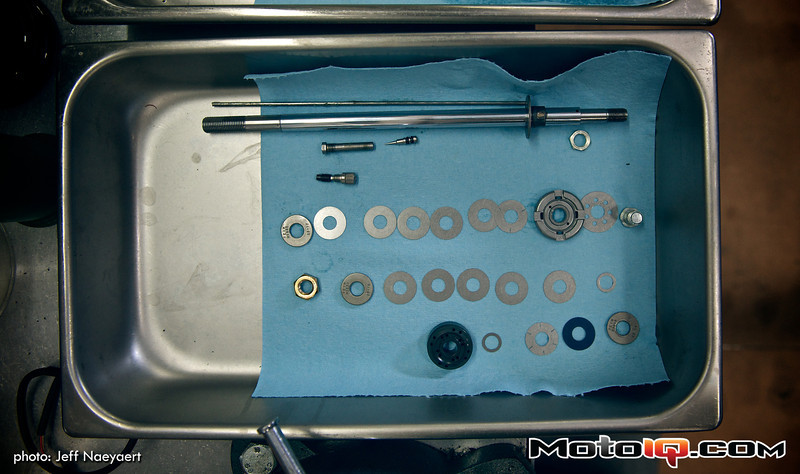

All TEIN suspension products, whether made in China or made in Japan, will be covered with our manufacturer’s warranty. That won’t change. In fact, we’ll continue to offer after-sales service, such as replacement parts and dampers, as well as overhaul service, to all of our customers so that they can continue to use their TEIN suspension for years and years.