As some of you may know, we do development specifically for the U.S. market. We’ve mentioned this before in our blog. A lot of people wonder why even bother with this step, especially if the same car is being sold overseas. Won’t those products fit just the same? Won’t it have identical ride and handling characteristics? Well, that may not always be the case.

Many countries have different standards for their vehicles to conform to, and as such, vehicle manufacturers have to comply with whatever regulations are in place for that specific region. In the U.S., crash safety is a heavily monitored factor in vehicle construction. And because of this, vehicles designated for the U.S. market tend to be a bit heavier with the safety equipment needed to pass the stringent crash standards we have. That’s not to say that vehicles overseas are not very strong or reliable, by the way.

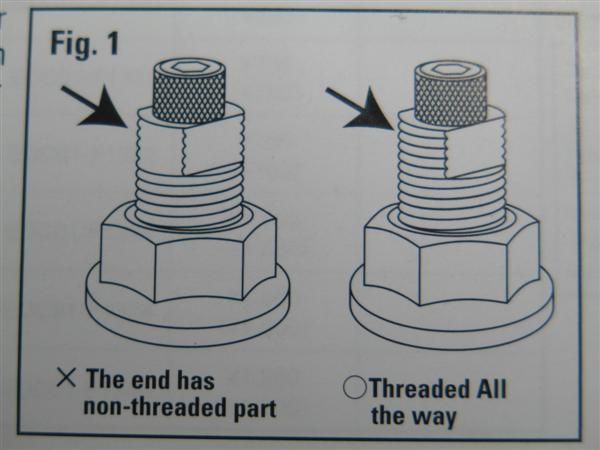

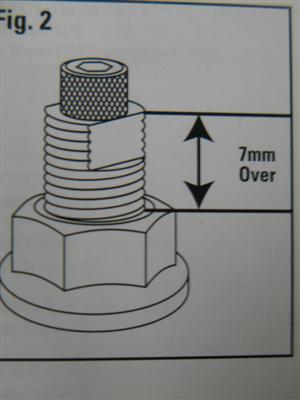

Because of these differences, we must test our products to make sure that not only fitment is correct, but that our desired ride heights, whether for lowering spring or height-adjustable coil-over, are to our standards. And in some cases, we do have to make parts unique to the U.S. market only.

It is a time-consuming process, if you can imagine. Since all products are made in Japan, there are several steps in getting prototype suspension parts made, then tested on a U.S. market car, and if all goes well, we can go right into production. In some cases, we have to retest from the first prototype if it’s not to our standard. *This is one reason why we don’t guarantee that a customer (who has loaned us their vehicle for our testing) will get product from us after testing- we don’t want to give them a product that may not meet our standards for ride quality and overall adjustability (if applicable). In those cases, we normally have to retest with another prototype. Once it meets our criteria for whichever model, only then can we continue with production.

What is difficult is gauging the market’s needs for performance suspension. With our various lines of suspensions available, each one has to meet criteria we believe fits our customers expectations. Of course, every person is unique in their own right. So to say that we can fulfill the expectations for 100% of our market is difficult to say. But we work on customer feedback and that helps us tremendously in determining what a customer is looking for in suspension. Above all, our main goal is to produce a high-quality product with great performance for its line at a cost that is reasonable. Because we cannot meet all customers’ expectations, we also offer our revalving service, allowing the customer to have the dampers reworked for a spring rate they desire. This service is more common to our customers utilizing their suspension for competition use only, but it is not limited to these people. We’ve modified off-the-shelf dampers for customers who altered their vehicles with items such as sound equipment (some cases, as much as 300lbs additional weight!) and used higher rate springs and revalved dampers. Sometimes the opposite is needed- vehicle lightening can require softer rate springs and damper valving to correct these changes, as it will affect overall vehicle dynamics.

By the way, offering this overhaul service (standard or revalve) for dampers also helps to maintain the longevity of the dampers. We recommend damper inspections every 30k miles.

There are some instances where we are working around a tight schedule to complete testing in time to make TEIN Japan’s production schedule. This is especially the case with newer vehicles already released. We try hard to make sure we have product in time to get it out to our customers. But sometimes it is still difficult to get the job done in time. As mentioned earlier, some prototypes need to be redone before we proceed with production.

We also have some opportunities to test at local race tracks and develop for various vehicle configurations. Some of our engineers dedicate their time for specific race teams for many forms of racing we are involved with internationally, giving us an extensive amount of information that can be useful in helping our customers determine what works best for them.

So it is a timely process for us. Although it would be easiest to carry over product developed for overseas, and much cheaper for us too, it isn’t the most practical solution in making sure we produce the best suspension kits for the money.

For more information on our Suspension Research & Development, and if you have a vehicle we are looking for, please visit the following link