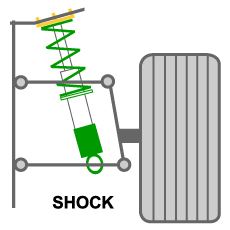

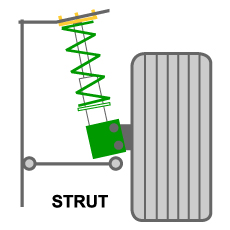

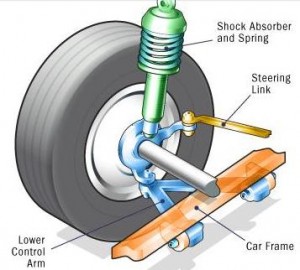

We’ve seen this topic come up as a discussion point for coilovers on automotive forums before. It’s a worthwhile discussion since many people will argue that this affects the “Made In Japan” label, or a “Made in Whatever-Country-We-Are-Talking-About” label, for that matter.

Why is this important? To us, it’s good to know because, while we do a majority of our manufacturing in Japan, it is clear that Japan is only so big. Certain raw materials clearly cannot come from such a small place, and other countries have industries that are better suited for manufacturing certain materials. Therefore, we must look to outside countries to source our materials, whether raw or preformed.

While we do manufacture such items like our springs, dampers, and even our spring seats/seat locks, we may have to source the alloys (in the form of wire, tubing, & billets or barstock) from countries such as China, Indonesia, Australia, and even from the U.S. It is all dependent on whether the materials can be sourced from each country, and whether those materials meet our standards for the products we make.

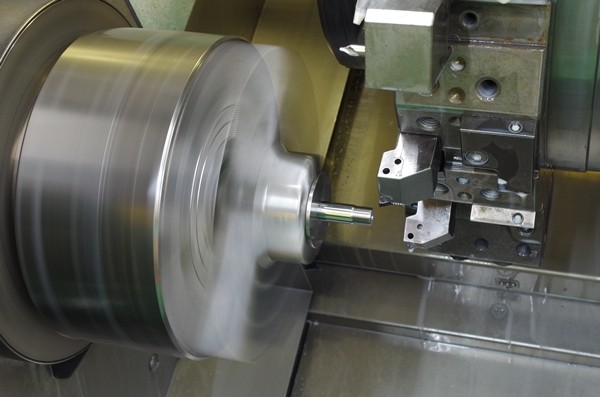

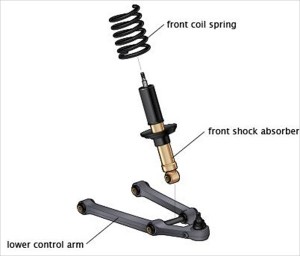

Extruded tubing that has been cut to length are placed in our automatic feeder for our lathes to be machined.

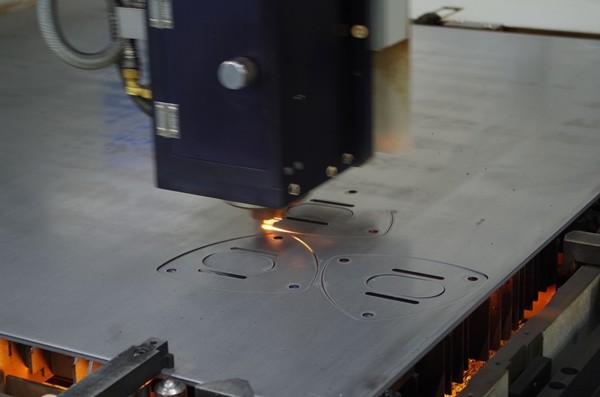

Our steel knuckle brackets are made in-house using materials (tubing and stamped steel sheet) sourced from other countries.

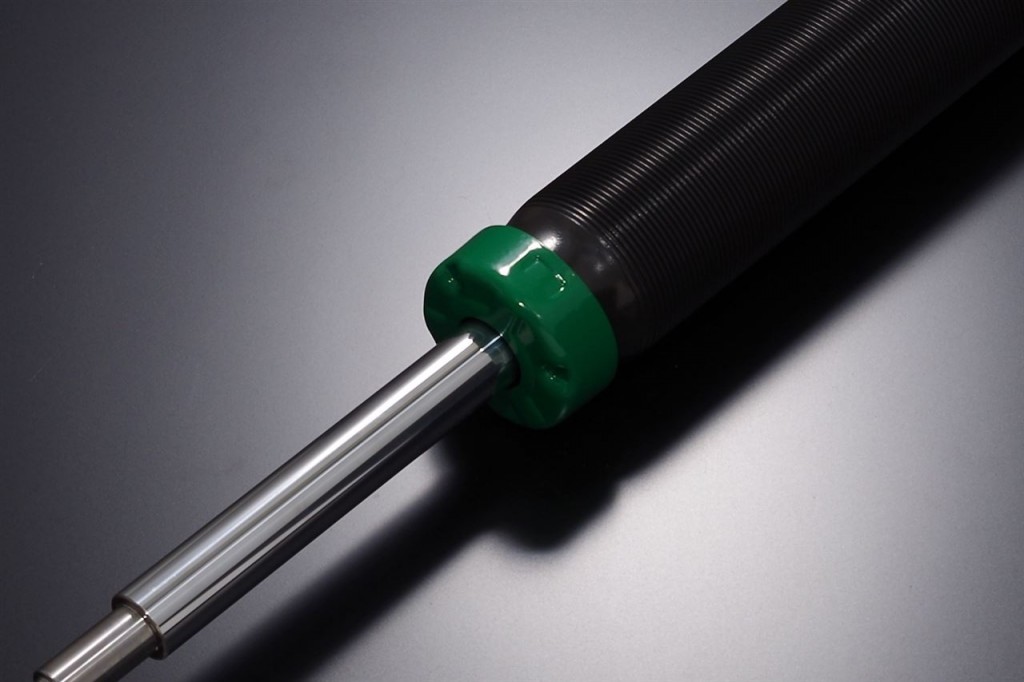

Our piston rods come in as long cold-drawn bar stock. We then cut to length, gun drill, machine, thread, & polish as necessary.

Items like our dust boots and eye ring bushings, which comprise mainly of rubber, come from China. This wasn’t always the case. In fact, we once had an issue with some eye ring bushings where the rubber bushing separated from the steel shell. So, we had to source some replacements from a Japanese manufacturer. But even then, we imagine the materials used by this Japanese manufacturer came by way of China. Still, we were able to resolve the matter, even if it meant recalling some of these Chinese manufactured bushings and paying a bit more from the Japanese supplier.

Steel, a very important part of TEIN suspensions, and a component that goes into our damper shellcases, upper mounts, and springs (in a different alloy), may also come from our Chinese suppliers.

Steel bar stock is cut to specific sizes in order to mount onto our lathes for multi-step machining. These will eventually become pillow ball cases for our upper mount assemblies.

Some of our electronics, such as our EDFC systems (EDFC Controllers) come from China. They’re designed in-house at TEIN Japan, much in the way that some of our Smartphones are designed by U.S. engineers, but made in China. Other components of EDFC, such as cables and stepping motors, come from Indonesia.

Small components, like nuts and bolts, can also come from an overseas supplier.

We don’t try to hide from the fact that some parts are made overseas and not from Japan. You can even see where some of these parts are made since we have to put the country of origin right on the packaging or on the items themselves.

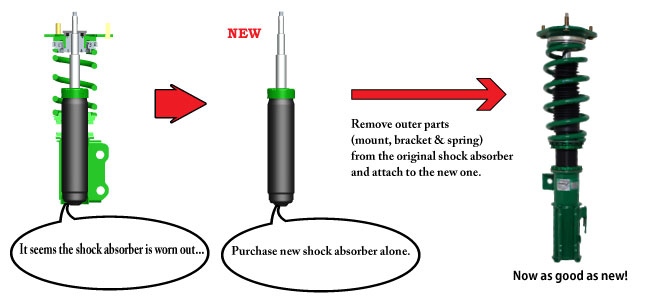

And again, our STREET BASIS Z & STREET ADVANCE Z line come from our TEIN China plant, our very own manufacturing facility (we choose not to outsource our Chinese made suspension kits). ***HOWEVER, regarding our springs for these suspension kits, we actually do import finished springs from Japan due to a quality concern we had with the first batch of coilover springs we were making in China.Fortunately we discovered this spring issue in our quality control tests, so these items never reached the consumer. Until we can get spring manufacturing in China corrected, we will continue to import the springs from Japan.

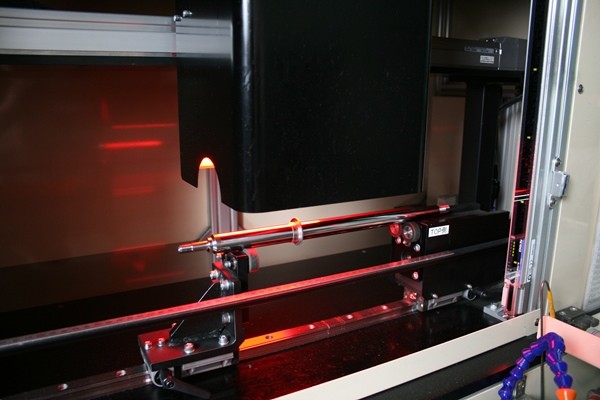

Also, as we do with each and every damper made in Japan, each and every TEIN China manufactured damper goes through our damper dyno to ensure proper damping force and function. It’s time consuming and not very cost-efficient, but we’ve got a reputation as a quality manufacturer to uphold. Until we can rectify the issue with our Chinese manufactured coilover springs, we’ll continue to import the springs from Japan.

Each and every component we use for our suspension kits goes through rigorous testing to make sure they meet our requirements well before they even make its way into one of our kits. EVERY COMPONENT. We push items like our dust boots and bump stops, even the thrust washer between the spring and seat lock, to the point of destruction, just to see exactly how long they will last and under what type of loads/stresses they are subjected to before failing. Coatings like our patented 2-Layer/1-Bake powdercoating, our pioneered low-friction ZT coating, and even our anodizing are placed in accelerated aging and salt water spraying to test against corrosion. You may have already seen our video regarding our lowering springs and how they compare to a counterfeit (in terms of spring design. not necessarily in terms of color and labeling). That’s the kind of testing that enables us to make the highest quality product for the money.

If we cannot find a component or material that meets our needs, we will do what we can to manufacture the parts ourselves. It may be costly for us to do it in that way, but it may sometimes be the only option we have.

Our in-house quality control section. All components are inspected and tested prior to making their way into one of our kits.

Piston rod inspection ensures defect-free finishing, critical in ensuring longevity and high performance function of our shock absorbers.

This is what differentiates our definition of “Made In Japan” compared to other Japanese suspension manufacturers, and we’re now redefining what “Made In China” or “P.R.C.” (People’s Republic of China) stands for. We push these statements well beyond the standard, and even beyond your very understanding. We hope that our customers know that, wherever our components come from, quality will be our highest priority well before you get your hands on our products.