Hey whats up every one. Since Ryan has posted proper EDFC motor installation, I’ll give everyone tips on solving any error codes you may encounter after installation or later on down the road.

A common misconception on the EDFC display are the codes. There are three different error codes: ER, EL and EE. A fair amount of people seem to think that there is “EA” error code = Error All. The actual code is “ER” , error right side motor on either the front side or the rear side. Yeah, it looks like an “A” but that is a “R”. The below image shows an error for the right front side since the error is displayed for Front.

Next, code “EL” which means error left. In the image below the error is on the rear left side because the “EL” is displayed for Rear.

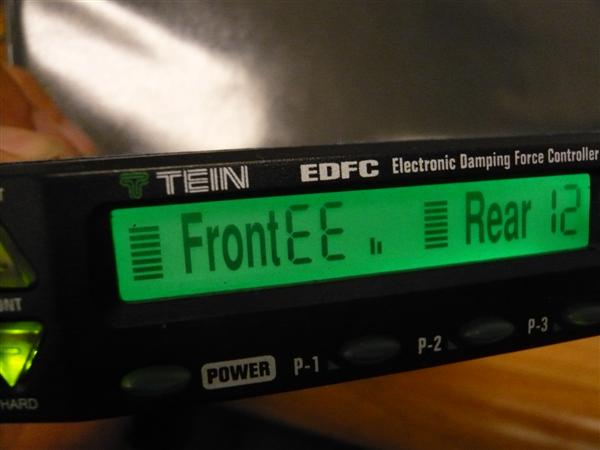

Lastly, code “EE” which means error on both right and left. In the image below, error right and left for the Front.

The error codes can be caused from several areas on or around the wiring and components. We will start with the most common source of the errors.

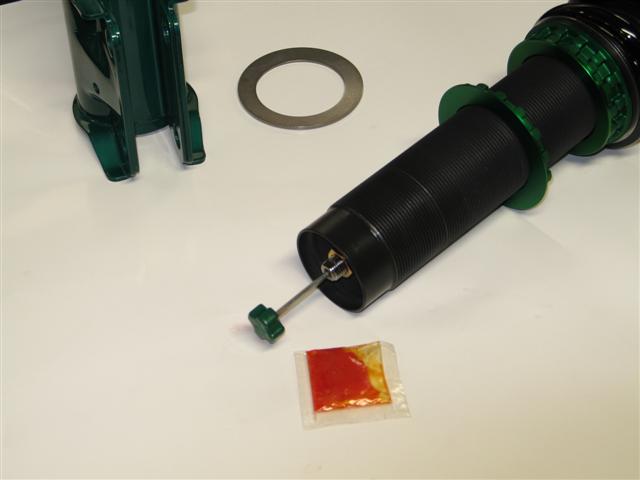

1) Harness plug between EDFC motor and EDFC wiring harness.

The terminals (pins) inside the plug can be pushed out slightly causing the connection to be lost.

You can see on this male connector that the pin on the right has been pushed back not allowing a connection to be made.

You can see the red wire on this female connector has gotten de-pinned.

Fix the problem by pushing the wire back into the plug and let it re-seat itself. When connecting the two plugs, hold the plug and wiring to ensure the pins do not get pushed out again.

If the wire has some stray or frayed wire not really holding on to the terminal, I recommend replacing the whole cable or motor to avoid damaging the control unit.

2) The harness plugs on the back side of the control unit are not plugged in completely. The thin white plugs for front and rear EDFC harnesses need to be plugged into the back of the controller perfectly. It should not be tilted as shown in the image below. So if your EDFC harness is pulling the connector to one side, it can easily cause an error.

Left and center plug correctly plugged in while the right plug is not fully connected.

Fix the problem by re-adjusting the harness. Changing the wiring route or using zip ties to secure the harness may help.

3) Frayed or damaged wiring. This is not likely on a brand new EDFC install. More the case on an EDFC system that suddenly starts throwing error codes. Depending on how the wiring was run throughout the vehicle the wiring could have become frayed or pinched over time thus causing damage to the harness and loss in connection.

The fix is to determine the problem area and repair or replace the wiring.

In a future post we will go over some trouble shooting tips for isolating EDFC problems.

Replacement parts can be purchased from the TEIN Online Shop or through a TEIN Authorized Dealer. To find the part number for the needed part please refer to the EDFC installation manual. If you no longer have your manual click the following link. If you have an older Silver EDFC Control unit the wiring and motors are different so please contact us for the correct part number – contact.