What’s up, people? Here I go again with some helpful tips when installing lowering springs and coilover kits.

I have to honestly say that we hear the following questions countless times during the work week.

“Why is one corner of my car higher than the other?” Or, “Why is my ride height uneven?”……………..(AHHH..here we go again)..lol.

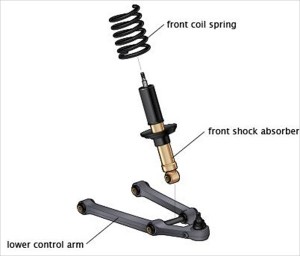

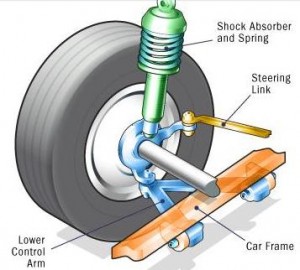

The solution is actually quite simple. The first things to check are for worn-out suspension components. We advise to check all components carefully and thoroughly. Anything can contribute to the issue previously mentioned. Worn out bushing, incorrect spring, blown damper, spring perches are not even, missing or mis-installed components, etc. If everything checks out fine, then the only candidate that would contribute to uneven ride height would be suspension pre-load. This issue is commonly encountered when installing lowering springs and/or dampers on vehicles with double wishbone or multi-link suspensions.

In some cases the lowering spring or coilover kit is installed while the suspension is in a full droop. This means that the bolts on the lower control arm were tightened while the arm was hanging down. In other words, there is no load on the suspension when tightening all components. When the vehicle is brought back down the bushings twist causing the suspension to not settle correctly thus resulting in a uneven ride height.

The first thing you want to do is lift the car back up. Them loosen the bolts on the control arm and shock absorber. Once in the air use a second jack to apply load on the control arm. This simulates as if the car was on the ground and the control arm is back to its original position. Then re- tighten all the bolts loosen in the previous step. Follow this process with all four corners, then bring the vehicle back down. If you follow these instructions, this should help get the vehicle to the correct ride height. Plus,

you will have learned another method on how to correct uneven ride heights, if you ever run into a similar situation in the future!