Lately one of our greatest developments to hit the mainstream in TEIN suspension kits is our Hydraulic Bump Stopper (H.B.S.) system.

This technology isn’t anything new. However, the current derivative is a much more affordable design, and has now made its way into coilovers like our FLEX A and FLEX AVS kits, and now our ENDURAPRO & ENDURAPRO PLUS shock absorber lines.

Why are we creating so much buzz about this system? Mainly because a comparable Hydraulic Bump Stop system isn’t typically found in passenger vehicles, outside of trucks where you’d have to opt for something like an externally mounted bump kit.

Even our current Hydraulic Bump Stopper system used in our FLEX A, FLEX AVS, & EnduraPro/EnduraPro Plus shock absorbers differs from systems used in rally suspension, which are typically much more expensive units and require rebuild. Our current system is more affordable to make and doesn’t require servicing (FLEX A and FLEX AVS dampers are rebuildable, but the H.B.S. system doesn’t need to be rebuilt, per se).

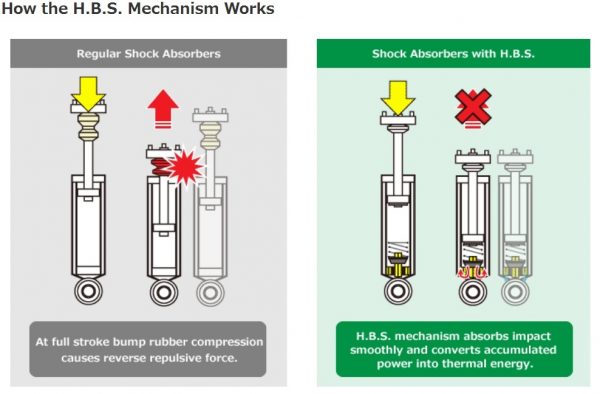

Still, all this hype we’re making about a Hydraulic Bump Stopper doesn’t mean much if you don’t know what it does. So, picture this: You’re in a fully loaded vehicle (max occupancy) and have the trunk fully loaded. Already you can picture the suspension starting to sag. Then, while driving, you hit a big speed bump. On any normal suspension, chances are you’re hitting the bump stops, which will do a great job of preventing the shocks from bottoming out. However, the consequence of hitting the bump stop is a harsh impact and resulting bouncy or wallowing feeling.

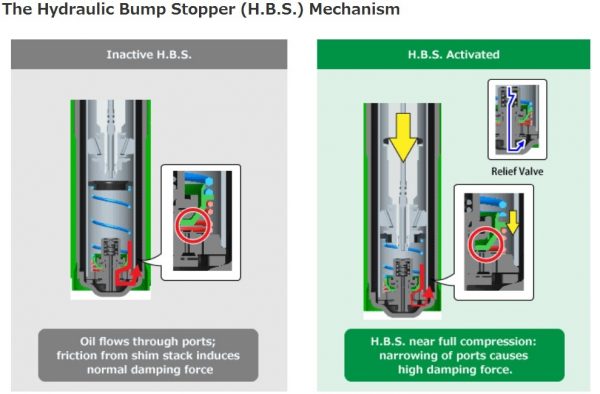

Now, a Hydraulic Bump Stopper eliminates this bouncy/wallowing feeling. It does so by creating more damping force towards the end of the damper stroke.

Typically our dampers are valved to offer a digressive feel, meaning that as piston speed (of the shock absorber) increases, it will only increase damping force to a certain extent, then it actually does not increase in force if piston speed is even higher. That is typically fine, but when this high piston speed is towards the end of the shock’s stroke length, it will have that harsh feeling (remember that bump stop?) we’re mentioning about.

Honestly, a damper with progressive or linear rate damping can still hit a bump stop and cause that harsh feeling.

But why does creating more damping force with the Hydraulic Bump Stopper help? Essentially it’s slowing down the piston of the damper. It gradually builds up this damping force so that the end result is a smoother absorption of force, while letting the damper rebound normally without oscillation.

When you see Stadium Trucks or Baja Trucks take on a massive jump, what you see on its landing is actually quite impressive. The suspension fully compresses, but as the suspension extends again, it’s nice and smooth. No crazy up and down oscillation. That’s what our H.B.S. system does, but for a smaller scale (shorter stroke length than Stadium or Baja Trucks, obviously).

Or, another example: Using lowering springs on OEM or replacement shock absorbers. While this setup is common place, and most work relatively well, some lowering springs might be too low of a ride height or too stiff a spring rate for the OEM valved shocks. A premium replacement like our EnduraPro line is a better match. Valved to offer a beneficial increase in performance, the added Hydraulic Bump Stopper is a nice addition because of the lowered ride height with lowering springs.

While our EnduraPro/EnduraPro Plus shock absorber line is a match in terms of overall length (compared to OEM), they offer larger internal capacity and more damping oil, and improved damping characteristics. So from a performance standpoint, these are a great upgrade for your lowering spring. Again, these include our H.B.S. system, and when lowering a car using OEM/standard replacement shocks, reducing that stroke length can mean exacerbated issues with ride quality and more chances of hitting that dreaded stock bump stop. You’d end up with similar ride issues in a fully loaded vehicle. Now we can resolve this potential issue by using the increased damping force the H.B.S. system creates further down the shock absorber’s stroke length!

It really is an ingenious system, and one that we’re glad to bring into mass-production. The fact that we can adapt this product into our replacement shock absorber line means that this feature is available to all consumers, whether their budget allows for just our premium shock absorber replacements only, or for those looking for greater handling performance (like our FLEX A or FLEX AVS coilover kit). We’re hoping to add this to many more of our products in the near future!