I still refuse to name other brands that like to bash on us. Really, it wouldn’t be hard for you to find for yourself. Just do a quick search online and you’re bound to find some type of “claim” about us. Or TEIN China, rather.

We were recently forwarded an email from one of our distributors in Europe. They received a sales email from a Chinese parts manufacturer, one that is well-known in the U.S. At least, in my opinion. Obviously they had concern regarding TEIN after reading the following from that email:

- News:

Nowadays, the brands – Tein establish factories in China to lower their price in this market. Our company has five branches in china, and knew Tein about half year ago, in that time, they are already sales their products in very lower price. After six months, their quality cause big problems for oil leaking. For their products, as long as the products are made in China, the oil leaking rate is over 50%. We are here to remind you, do not over care about Tein’s lower price products.

Recently, our sole distributions observe that there are some new Taiwan brands who offer lower price in this market. In fact, those new brands all come from some small underground factory, and they specialize in manufacturing counterfeit products from other famous brands. We have the survey of Taiwan’s brand from Hong Kong’s magazine which include some pictures and capital of each company. We can send the information for you to provide to your customers as reference in your country if you need.

Apologies for the terrible grammar in that excerpt. That’s what it says. I unashamedly copied and pasted.

It’s quite obviously bothersome to us. We only recently launched the new STREET BASIS Z & STREET ADVANCE Z, which are the only two product lines currently coming from our TEIN China factory. Yet, this company, who has decided to go public with “facts”, states that our TEIN China dampers have a 50% leaking rate. These new dampers were just made available in May. I’d like to know where they got this claim from.

Are our new STREET BASIS Z & STREET ADVANCE Z lines cheaper? Absolutely. We decided the only way to address our customers’ concerns is by being able to produce a suspension that our customers could afford. HOWEVER, this was not to be done at the expense of quality. Cheaper in cost is our goal, not cheaper in quality.

We own this TEIN China factory (and it is only one factory. not multiple as the email excerpt implies), and we control all aspects of its operations and product development. We would never, NEVER, release such faulty products with a supposed 50% leaking rate to our customers.

I made mention of the official release of the new STREET BASIS Z & STREET ADVANCE Z lines a while ago. I stated that there was a delay in the release of these due to quality concerns. However, the concern was due to noise from the damper during function testing. NOT LEAKING. This is exactly why we had to delay the release of these suspension kits. Again, these products never made it into customers hands.

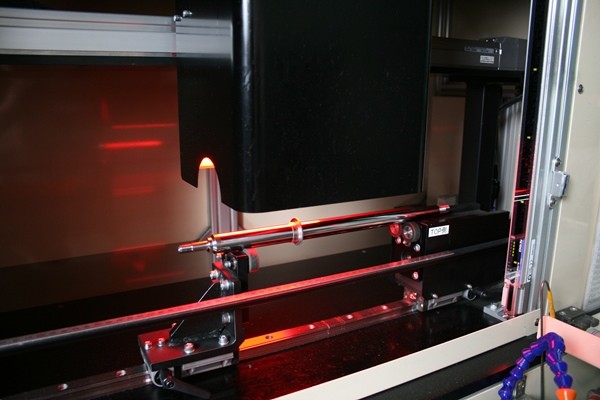

The below pictures are from a magazine that visited our TEIN China factory during a media day. They got to take a look at what goes into our damper manufacturing, and took a lot of pictures regarding piston shaft inspection, among other processes.

TEIN China staff put components through the same stages of inspection and cleaning that TEIN Japan manufacturing employs. In fact, much of the machinery used in TEIN China is the same as in Japan.

Piston Rods going through our scanner for any defects. Piston rods that do not pass will be discarded for scrap.

Even extremely small imperfections on piston shafts will be reexamined by staff to verify what our scanning machines discover.

TEIN China was a huge undertaking for us. We’re not outsourcing manufacturing of our kits. We’re doing this ourselves. We’ve got a lot invested in this operation, and we’re not going to skimp on quality to provide you, our customer, with half-assed manufactured products. Quality, and ultimately your safety, is of utmost importance to us, and quality will go into every suspension kit we make. Safety, high quality, & reasonable prices. We must meet all three of those requirements. No exceptions.

I must also note that each and every damper coming from TEIN China goes through damping force check on a dynamometer. This ensures correct function of each damper prior to packaging.

Does that guarantee that a part will never fail? Absolutely not. However, putting as much effort as we do into our manufacturing reduces the amount of parts failures. Even with that said, we stand by our products and will assist our customers to the best of our abilities should they have claims of their own.

So, while I refuse to name drop this Chinese suspension company trying to bash TEIN China, I will say this: Purple. I will also say this: Mighty Ducks Part II.

So, anywho, do not over care about that kind of stuff……….. whatever that means.