Now, I’m not about to bore you with technical information on exhaust designs since there is already a plethora of information and opinions on the benefits and downsides of each type of design. But exhausts play an important role in power production for our cars. I cannot say outright that it is an area most people tend to overlook. However, it is a factor that is often overlooked when it comes to the expectations we have. There are so many exhaust brands out there, and all of them follow their own tuning style.

For most of us, our cars are our daily drivers. And maintaining drivability is a very important aspect. I don’t know about you, but I like keeping the powerband nice and smooth, as well as accessible from the 2500 to 4000 rpm range. I definitely don’t spend a bunch of time motoring at redline. No thanks.

But really, it seems that we are all convinced by advertisements and forum posts (if you follow those) that show that bigger piping size is better. Is it, though?

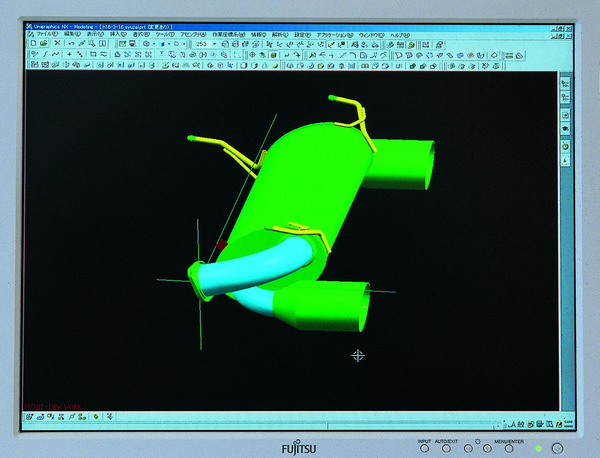

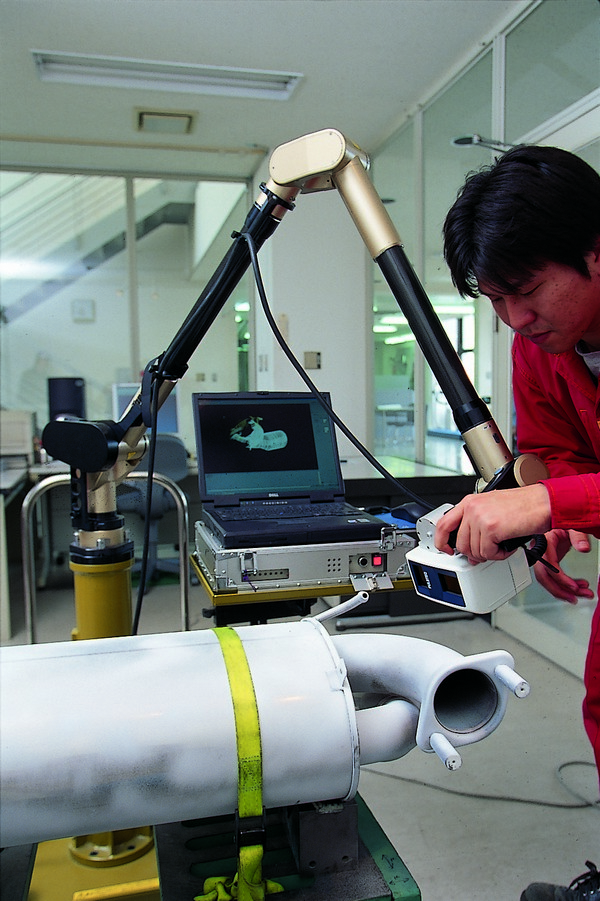

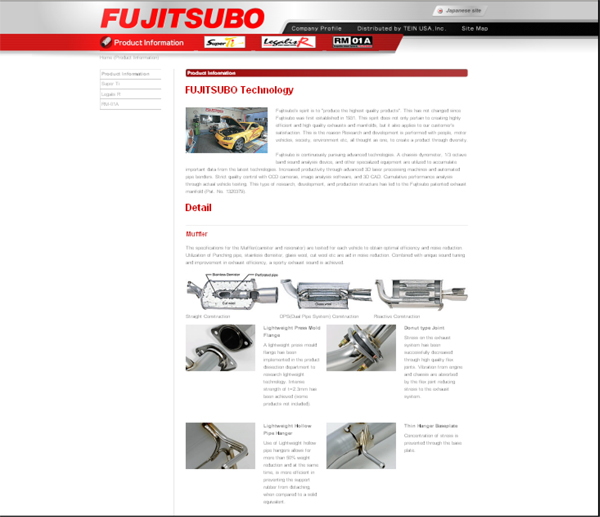

When we had an engineer from Fujitsubo stay with us in the U.S. to develop exhausts specifically for the North American market, we learned a bit more into exhaust design and what makes Fujitsubo exhausts unique. Of course a main factor would be to make more power. Second was material selection for their Stainless Steel and Titanium exhausts. Third was reduced weight over factory exhausts. And lastly, a combination of great sounds and great looks.

Taking a look at the RM-01A I have on my car (part number FJ 190-63055), I never knew how much attention to detail Fujitsubo had put into it. They really do stand by their quality.

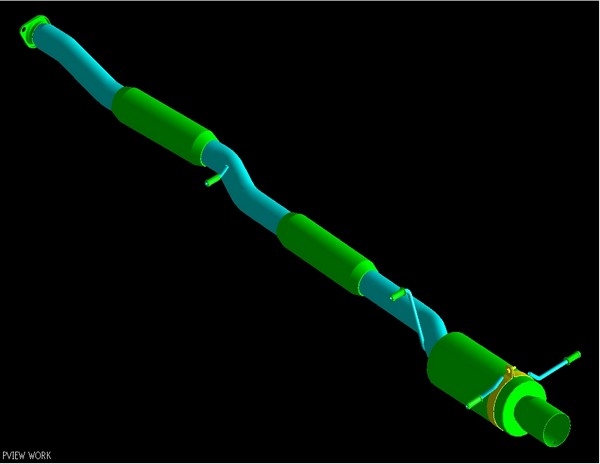

Inside diameter is 76.3mm, but it retains the donut-type flange from the downpipe, which matches my aftermarket downpipe (as well as stock) perfectly. Even though this means there is a slight step in piping diameter at the flange (63.5mm), it also means less stress at the flange where the two pipes meet. The rear canister also has a reducer of the same size. This helps to reduce decibel levels to a very low 86dB. Fujitsubo does sound tests using SAE J1169 standards.

Weight reduction comes in the form of 1.0mm thick SUS304 for the piping, resonators, and cansiter. Also, hollow hangers are used, as well as stamped 1.5mm thick gusset flanges (Fujitsubo’s SuperEX exhaust manifolds use Lost Wax formed flanges).

Minimal bends in piping also help to reduce restriction, and the rear canister is slighly canted. Fujitsubo even paid attention to ground clearance, and create an exhaust package that fits factory mounting points as precisely in the stock location as possible.

Overall, I am quite happy with the performance and sound. As I had mentioned, I like a very drivable range of power at relatively low to mid rpm range. I kinda threw that out the window with my turbo selection (a bit laggy for a 2 liter). But with this exhaust, I have regained good midrange power. Torque is nice and flat from 2800-6000 rpm and the motor pulls nicely up until 6500 rpm, at which point my injectors begin to max out. But again, I keep it low rpm on the street. Afterall, that’s where it spends most of its time. The RM-01A is aimed towards users that want good mid to high end power gains, which more or less suits my needs. Since I asked my tuner for a conservative tune, I feel like I was able to achieve what I was looking for, even with the extra lag my turbo gives.

So, while I won’t be needing max power right now, this setup seems to be a great match. As a consumer, you have a lot of resources to find what will suit you best. So do your research.

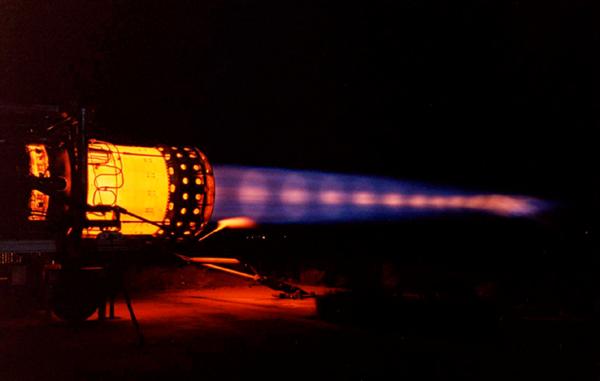

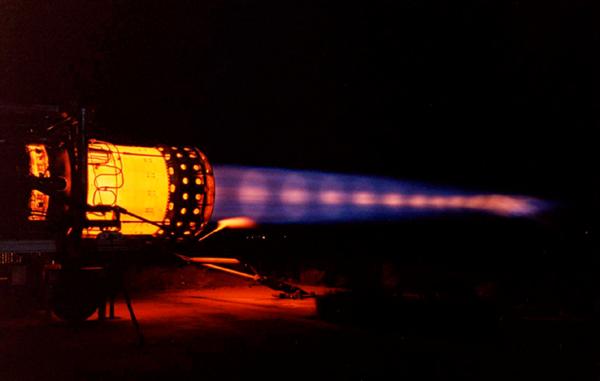

I suppose there will be a day when I’ll want a crazy high horsepower, flame-spitter of a car. When that day comes, I’ll be doing this

Imagine being able to spit out shock diamonds like this!!! I’m a nerd.

Bye bye