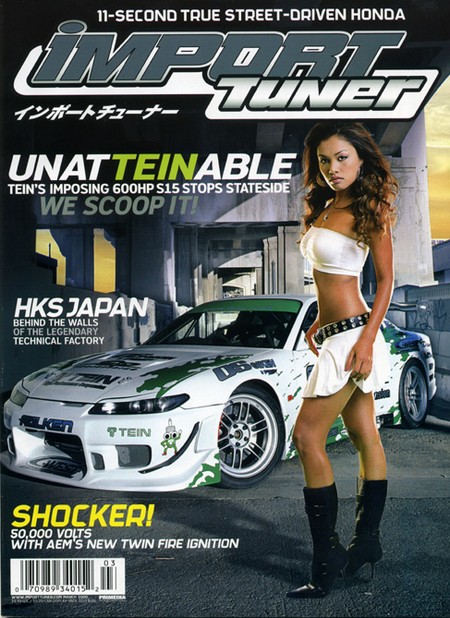

Recently saw on facebook that Import Tuner magazine is running a contest to see what the next cover car should be. One of the front runners is a white S15. It reminded me of when the TEIN S15 was on the cover of Import Tuner.

March 2006 issue. Click HERE to read the article.

Back in 2005 when drifting and time attack were blossoming in the US, TEIN decided to build a monstrous demo car. The purpose was to build a single car that could compete in select drift and time attack events. Prior to this decision we were sponsoring or borrowing cars to compete under the TEIN name.

One of our engineers who had some fabrication and rally racing experience was put in charge of the project. I obtained parts and helped with final assembly when I was not working on our 2006 Civic Si Coupe (also debuted at the 2005 SEMA show). I do not think our bay door closed for an entire month. Some of us worked, ate and even slept at the office to get the two cars finished.

This picture was probably taken at 2 or 3am a few nights before the cars had to leave for Vegas.

In the end the S15 was completed just in time to display at SEMA.

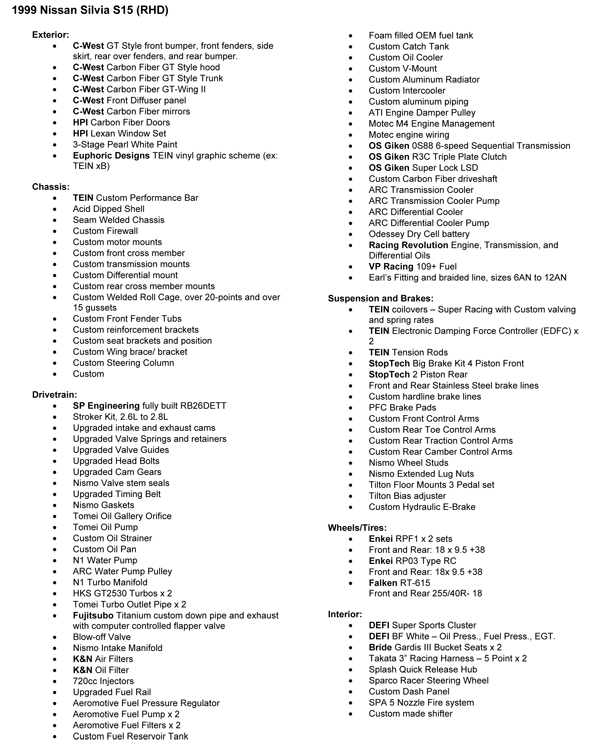

Under the hood sat at RD28DETT which was pushed back over 10″ to improve weight distribution. The motor was fully built from top to bottom with HKS parts and produced an easy 600HP and 550ft-lbs of torque.

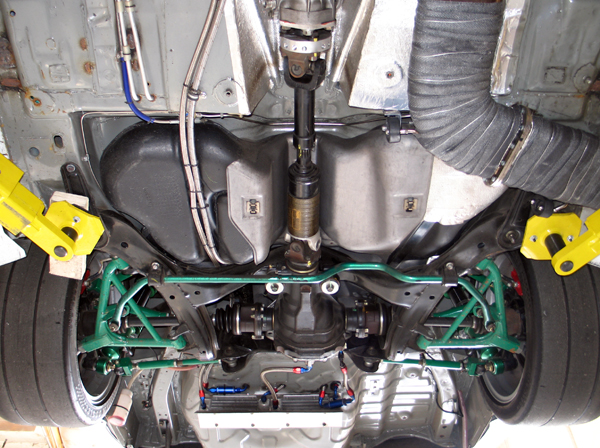

There were tons of custom parts including Ikeya Formula arms to widen the track, tubed front and rear fender wells, v-mount rad/ intercooler, crazy jungle-gym like cage, gussets everywhere, this car could have probably launched off a cliff and nothing would happen.

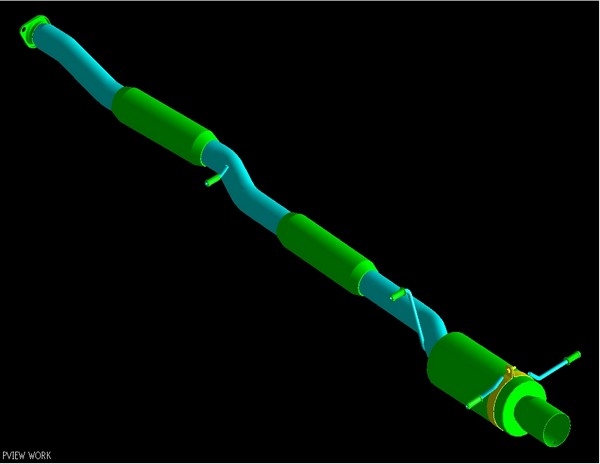

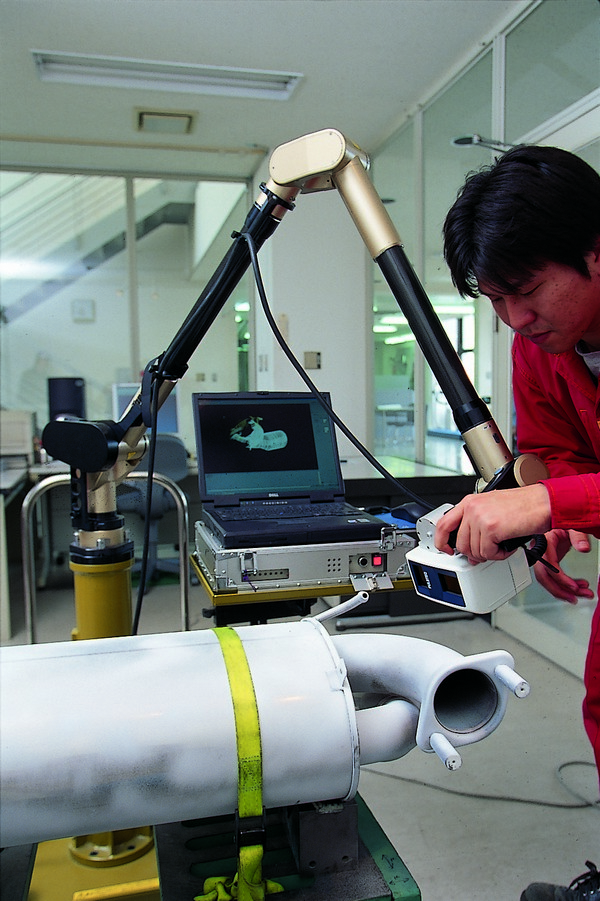

Ikeya custom arms, custom composite driveshaft, ARC transmission and Diff coolers, Fujitsubo custom flat side exit exhaust.

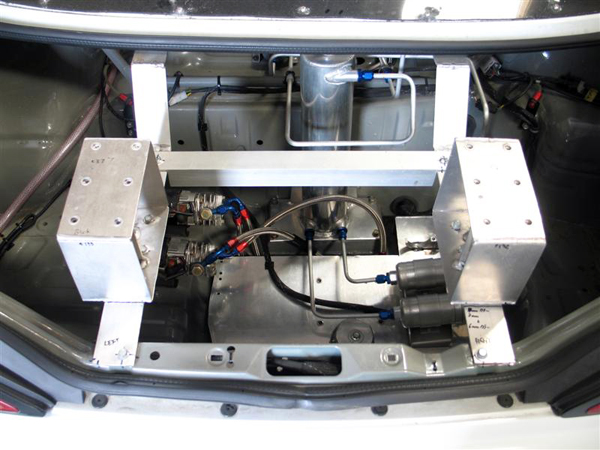

Custom fuel surge tank, dual Bosch fuel pumps, ARC pumps for the trans. and diff., halon nozzle, plus last minute fabricated aluminum wing supports.

DEFI Super Sports Cluster, dual EDFC, floor mounted pedal assembly. Not much room since the trans. tunnel was remade to fit the OS Giken 6-speed sequential and because the engine was so far back.

Over the next couple of years the car shipped back and forth from Japan. While in Japan it displayed at Tokyo Auto Salon, and had work done by MCR.

A quiet day at Streets of Willow for the car’s first shakedown. It was pretty awesome to see the car run for the first time.

In the end we ran the car twice at Super Lap Battle but the results were nothing special. Not enough testing and tuning to really get it properly dialed-in. Our engineers re-focused on product development instead of trying to be a race team, which we are not.

This car always reminds me building cars is about the right combination of parts and proper testing/ tuning. The TEIN S15 was constructed with a plan, had high-end quality parts and tons of fabrication but in the end maybe the combination just wasn’t right. Hopefully we will see the car re-emerge one day.