Quite often we’re asked about our lowering springs and if it’s okay to use with factory shock absorbers, or OEM, or even OEM replacement shock absorbers.

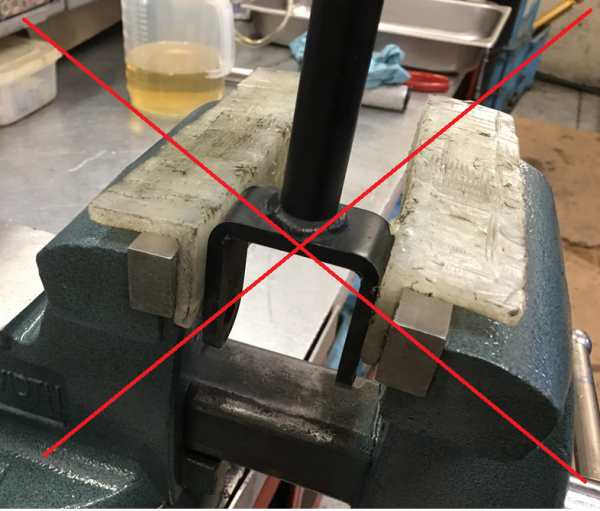

The easiest answer is yes, especially if they’re actual OEM factory shock absorbers. We can say yes as well for aftermarket replacement shock absorbers, but there is somewhat of a caveat. The issue is with the spring perch on shock absorbers or struts that have them. For our ENDURAPRO & ENDURAPRO PLUS premium replacement shock absorbers, we use 3D modeling of actual OEM shock absorbers to make our spring perches, then just modify the design so that it fits over our larger bodied shock absorbers. However, there are some instances where we make modifications for increased strength where we feel it may be necessary. This 3D modeling allows us to make very exacting designs so that it will work with OEM coil springs. And with that, we make sure that our S.TECH and HIGH TECH lowering springs have very similar designs for top and bottom coils to match the OEM coil spring.

Why we say there’s somewhat of a caveat with using our lowering springs on other aftermarket shock absorbers is because we’re not too sure how they model their spring perches. Some may use 3D modeling or a mold to create a negative simliar OEM type spring perch. However, we have seen some differences between some aftermarket replacement shocks and the OEM shocks they’re supposedly modeled after.

Besides the design of the spring perch (if applicable), our lowering springs are not intended to be very aggressive in terms of spring rate. This is intentional, as we expect that many customers are planning on installing our lowering springs onto OEM shock absorbers. With that, we have to keep in mind the OEM shocks damper valving and whether or not it can handle a specific spring design.

Another unknown variable with aftermarket replacement shock absorbers is how they’re valved in comparison to their OEM counterpart. Referring back to our ENDURAPRO & ENDURAPRO PLUS shock absorber line, we decided to “optimize” damper valving. Now, this optimization may vary by vehicle model. But it most cases we’re actually increasing damping force (slightly stiffer). Again, there’s a bit of a variable, because we may increase/decrease compression or we may increase/decrease rebound damping force, or a combination of both. There’s no set method of how we decide to valve. In some instances we may actually decrease damping force, especially compression, if we feel the ride quality will benefit from that change. But for other aftermarket replacement shock absorbers, we cannot say the same thing. In fact, when we’ve tested some aftermarket replacement shocks to their OEM counterpart, we’ve wondered why some of these aftermarket shocks are quite a bit softer (we’ve yet to see the opposite- stiffer than OEM). This can pose some interesting results in ride quality when comparing certain aftermarket replacement shock absorbers with our lowering springs, regardless of them not being very aggressive.

We’re not necessarily trying to pitch our ENDURAPRO or ENDURAPRO PLUS shock absorbers (how can we resist, though?!). But just know that ideally an OEM shock absorber will suit you best since that is what we designed our lowering springs to work with.