Our friends at MotoIQ decided to stop in and have their Type FLEX coilovers for their Project Supra rebuilt! While they were here, we gave them an inside view of our overhaul process. Not necessarily something we allow the public to see first-hand. But, we are talking about MotoIQ here, guys that like to nerd the hell out on car stuff. We couldn’t easily keep the door closed on them! Lol!!!

This Project Supra of theirs is pretty nuts to begin with. So we were glad to see that they wanted to continue the use of their older Type FLEX coilovers. However, we thought it would be a great idea to update the internals to the newer STREET FLEX setup. So, we had our in-house engineers work closely with the MotoIQ staff to get their dampers to the lastest specifications from TEIN!!

We had our R&D staff take them through our overhaul process and show, from start to finish, what goes into our rebuilds.

After a disassemble of external components (lower brackets, seat locks, upper mounts, springs, dust boots, & bump stops), we can start complete teardown of the damper itself. Our dampers require some unique tools for some parts of disassembly, which is why we do not offer rebuild kits to the public. We ask that all customers send their dampers to us for servicing.

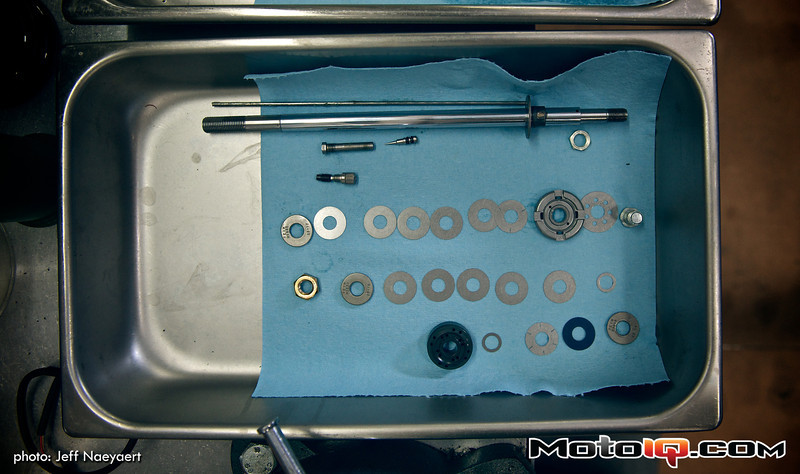

Once completely torn down, we can get to work on the internals. The piston shaft is broken down into several components. Once we can loosen the lower nut on the piston shaft, the piston valve assembly, including all shims and washers, can be removed. These components will be replaced with new ones. Whenever possible, we want to keep rebuild costs as low as possible for our customers, so we will try to reuse components that are still in excellent condition.

Once we can completely assess the condition of all components, we can then get to work on rebuilding. In MotoIQ’s case, we had to make some modifications to make the newest STREET FLEX setup work with their coilovers.

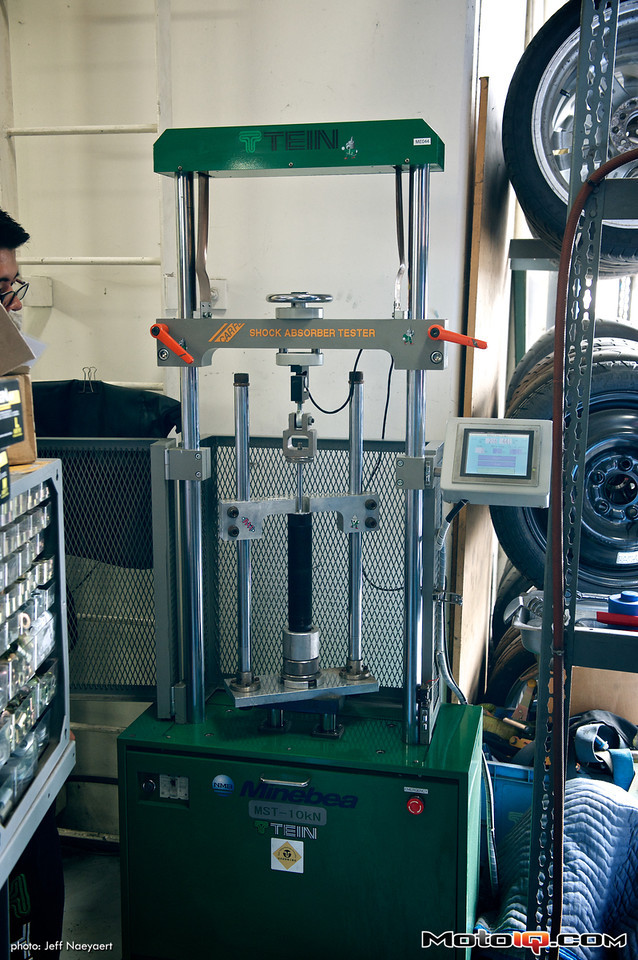

After all the necessary modifications are completed, we completely assemble the dampers, fill with nitrogen, then run them on our damper dyno and make sure they meet performance specification.

All other external components can then be reinstalled and the completed dampers sent back to the customer! All that’s left is to install, check/fix alignment, and enjoy!

We look forward to the next installment from MotoIQ on their Project Supra! They also have our EDFC Active to test out, so we’re sure they’re busy nerding away with that!

Please note that our overhaul and revalve service is available to the public. So, if you have any questions on our overhaul services, please give us a call at 562-861-9161 for more info! We’re glad to help!!!

In the meantime, please visit MotoIQ for some great technical information and follow along on their Project Supra build!

Project Supra Hits 800 WHP!:

Industry Insider: TEIN’s Shock Service:

http://www.motoiq.com/MagazineArticles/ID/3743/Industry-Insider-Tiens-shock-service.aspx