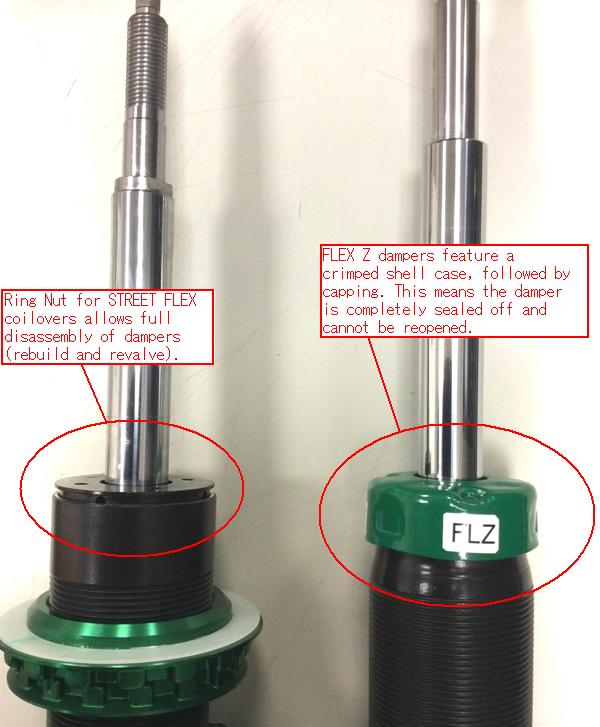

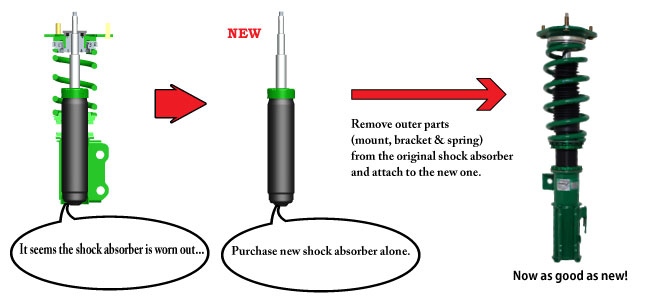

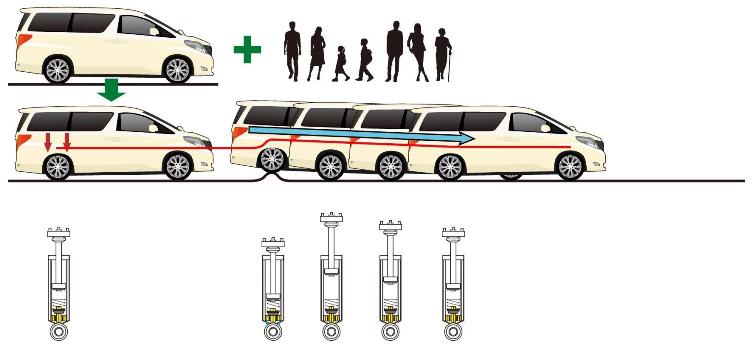

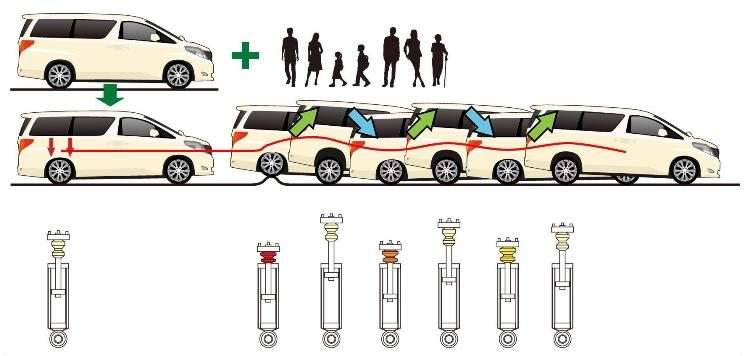

Well, by now you know that we are able to service our suspension, whether it is a damper rebuild, or in the case of the new STREET BASIS Z, STREET ADVANCE Z, & FLEX Z- replacement single dampers can be purchased.

So then, why is it still important to maintain your suspension?

Quite simply- cost. Just because we can service our suspension, it doesn’t make it a wise idea to run them dirty or to not periodically inspect the dampers and all its components for any wear, or to make sure they’re torqued properly (spring seats/seat locks, nuts, etc.). We don’t feel it to be necessary to spend a lot on overhaul. I mean, we appreciate the business and all, but we don’t appreciate your screaming when you get shocked by a rebuild quote. Lol.

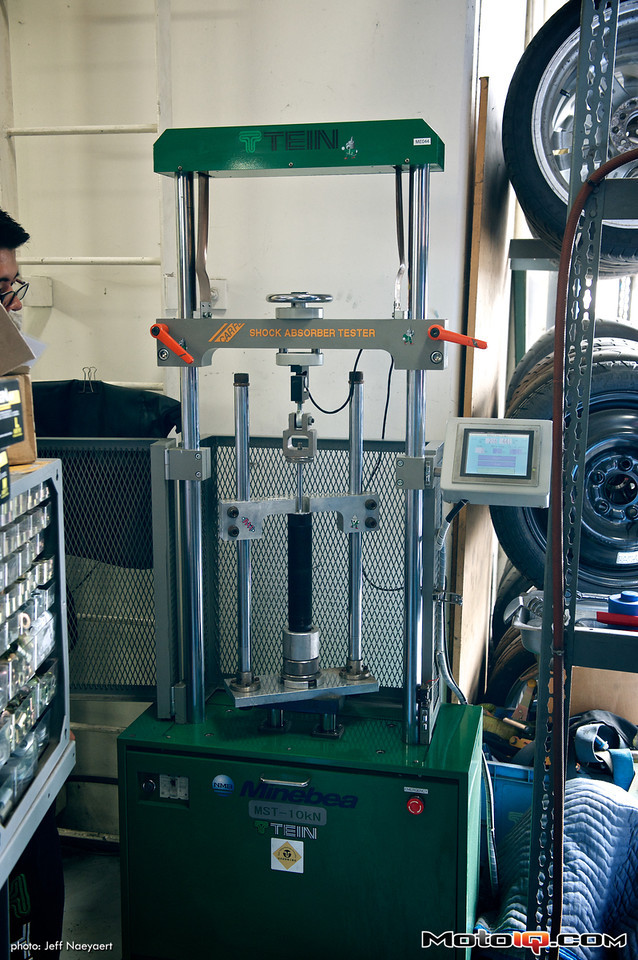

We say this because it isn’t uncommon for an overhaul customer to complain about our overhaul prices. Yes, we do have a base overhaul fee. This fee covers the replacement of seals and o-rings, refreshing damper oil with new damper oil, recharging with nitrogen, and of course the labor to do this work. But, components such as the piston shaft, ring nut, piston guide, piston valve, these are all extra components that get added above the base overhaul fee’s cost if we find it necessary to replace. Lately, we’ve been seeing 5-10 year old coilover sets hovering around the $200 (each damper) range for a rebuild. That amounts to about $800 a set. Nearly the cost of a new coilover kit, depending on the model.

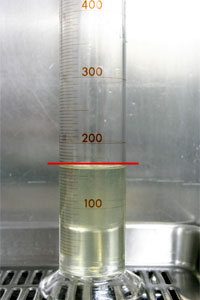

One of my favorite pics from Jonathan Wong at Driving Line when he came to check out our overhaul service. Damper oil should never look like this. That is way too dirty and shows that the damper was drawing in dirt as it cycled (probably through a blown seal). This can wreak havoc on the dampers’ internals, and bring overhaul costs to some exorbitant amount.

Don’t get me wrong. If I personally saw a rebuild quote near that amount, I’d probably bust a vein on my forehead. I’m no different than a lot of consumers. Money is tight, yo! I can’t be spending on unnecessary things.

Back to damper maintenance- It’s actually really easy to do. And, if you can’t do it yourself, take it to any of our authorized dealers for service.

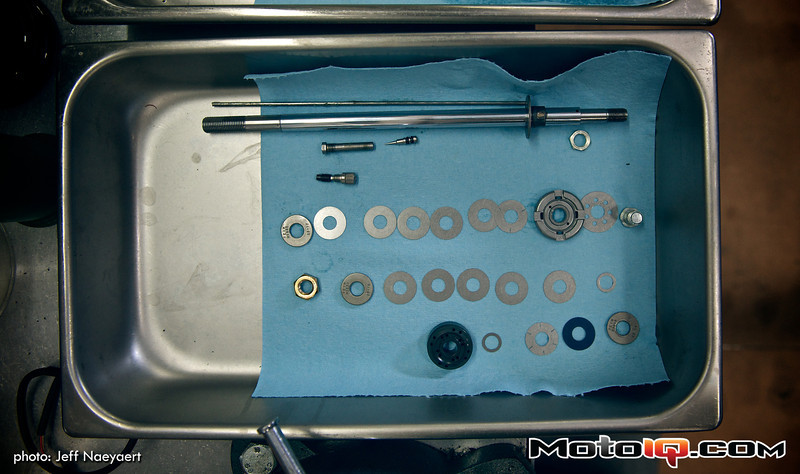

Pretty crusty, mang. That’s way too much dirt on the threads. May not look like a big problem, and for the most part it should come off easily. But it some cases where this type of dirt gets lodged into the threads and seat locks/spring seats, it can cause them to seize. The only way to remove- cut them off.

Honestly, simply keeping your suspension clean is the easiest step. Suspensions sit inside the vehicle’s wheelwell. This exposes all its components to the elements. Road debris such as dirt, gravel, mud, road salts (in places where it snows heavily), and such, can all adhere to the damper body. This can get lodged into so many places that can cause damage- threads where the seat lock/spring seat assembly adjust for ride height, around the dust seal at the top of the damper (where the piston shaft slides in and out of), around the pillowball mount (if applicable for your coilover application). This dirt can get stuck in any of these places and cause seat locks/spring seats to seize or piston shafts to get scratched.

Why this is a problem is excessive wear. A seized seat lock/spring seat will be increasingly difficult to remove and adjust. In some cases customers send in their dampers just so we can cut them out and purchase replacement pieces. That’s an unnecessary cost to me. Those things should last about the whole life of your suspension.

Scratches on the piston shaft can cause the nitrogen charge to leak out, affecting damper rebound, and eventually affecting damper life as oil can eventually leak out. And when oil leaks out and owners continue to drive for several hundred or thousands of miles, it causes more internal components to wear out, only adding to overhaul costs.

A piston shaft scratched, but not by dirt. Actually, the customer tried using pliers to hold the piston shaft in place while they tried to tighten down the nut to secure the upper mount to the coilover assembly. Still enough to cause problems to the damper and excessive damage to the dust seal.

Worn threads due to cross-threaded nut installation. Again, not typical wear and definitely not something we’ll be able to repair. A new piston shaft needs to be ordered for this case. That’s an extra $40 on top of the base overhaul fee.

We realize this sounds like a lot of work. After all, you’d have to get the car off the ground, wheels out of the way, then go into each wheelwell and clean up the dampers. But, so it goes in the world of adjustable suspension. You pay good money for high performance handling, but it doesn’t mean your car is maintenance-free.

Seriously, take the time to clean your dampers. It can be twice a year (in areas where it doesn’t snow), or 4 times a year. Be adamant of making sure your suspension is in tip-top shape. Also, while you’re down there, inspect your dust boots and bump stops. Those should have good pliability and no tears. Dust boots are a good preventative measure in keeping dirt away from the piston shaft and dust seal.

We hope this helps all you performance suspension owners a little bit, for whatever it’s worth to you. In the end we want you to enjoy your suspension for as long as possible, without having to spend a bunch of money to make sure it runs properly.