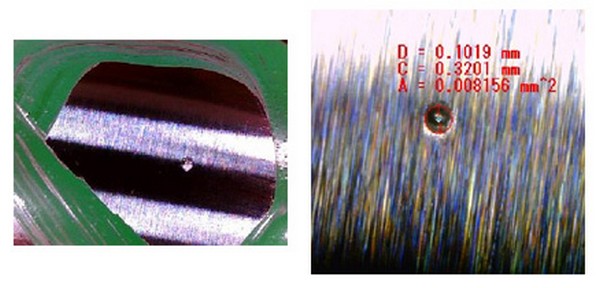

We have received many overhauls over the years, a lot of the times we Highly suggest to change the piston rod out due to scratches, dents, pinhole damage. Below you will find the images of why we highly recommend to have them changed.

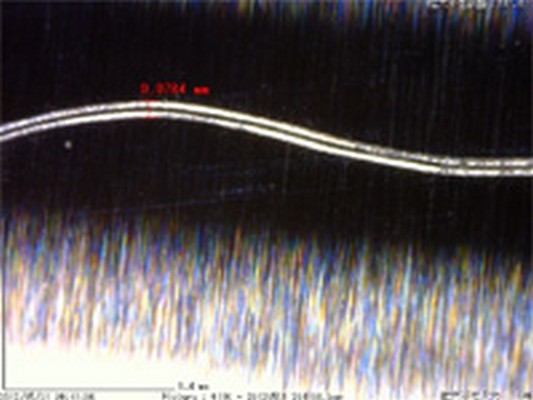

Above is the Microscopic view of a Pinhole damaged Piston Rod. As you can see if the piston rod is reused like that, that pinhole can rip or damage the new seal, and gas can leak from where the pinhole contacts a portion of this seal due to improper sealing.

Above is the Microscopic view of a Pinhole damaged Piston Rod. As you can see if the piston rod is reused like that, that pinhole can rip or damage the new seal, and gas can leak from where the pinhole contacts a portion of this seal due to improper sealing.

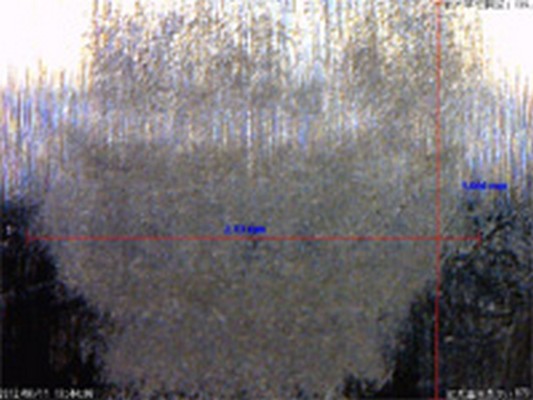

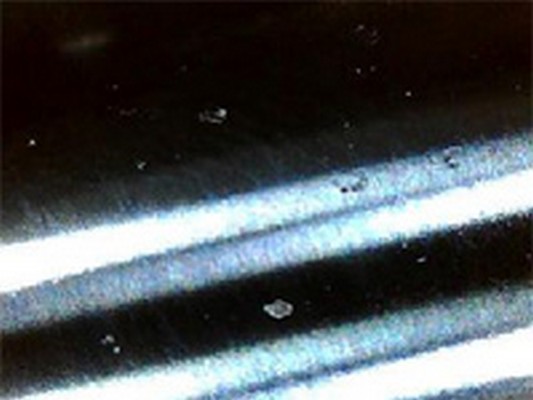

See on the image below how it can have multiple damages that would require to highly change the piston rod for a new one.

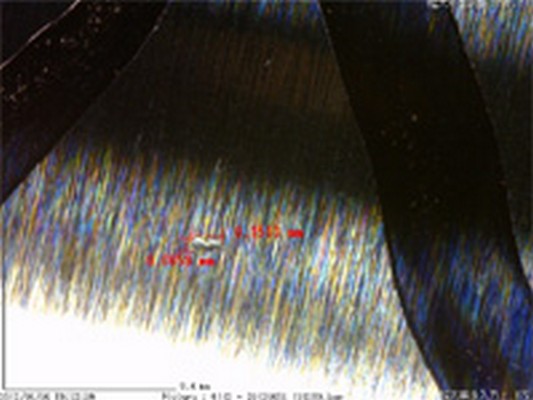

The image below is of a Microscopic image of a Linear Scar on the piston rods. This would need to be changed due to that deep liner scar. Same problems can happen where the dust seal may be damaged from contact with this scar, and gas leaking past the seal since the scar creates a gap (improper seal).

Scratches on the piston rod are one of the most common. Below you will find the Microscopic image of the scratched area will give you a better understanding as to why we would need to change the piston rod for the rebuilt.

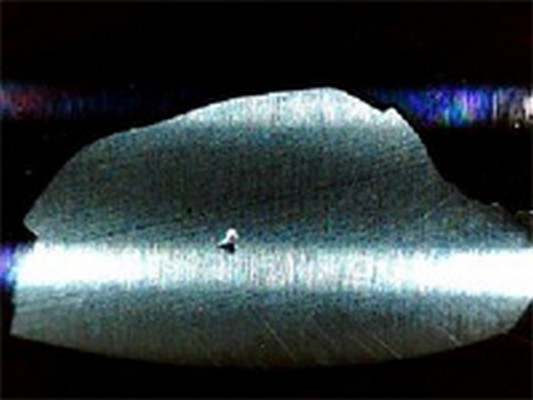

Last but not least would be the Microscopic Image of the Dents, these dents can be done to the piston rods from any rocks or debris on the road.

This is how it would normally look on the piston rod without the microscopic image.

As you can see why we would highly recommend to have these type of piston rods changed. All of these could have been one of the major problems that might have blown your dampers initially.

If you have any questions regarding our overhaul services and/or pricing, please feel free to contact us.