Back again with some more useful tech info this time for EDFC fitment verification.

We are always receiving calls regarding EDFC fitment on older kits or kits which may not have any details of EDFC compatibility. I was able to obtain some info on some specific areas ,clearances, and measurements that should be focused on when checking for compatibility.

Checking piston shaft compatibility

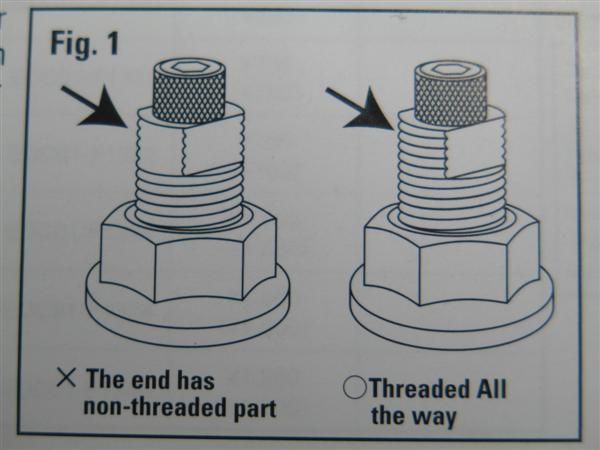

Inspect the top threaded portion of the of the dampers piston shaft making sure that the shaft is threaded all the way to the top of the shaft. Some shafts may have the flat machined edges, but the threads continue on the other rounded sides. Those can still work. The other type as shown below would have an area around the top of the piston shaft with no threads which not allow the EDFC motor to mount up.

Measuring piston shaft thread amount

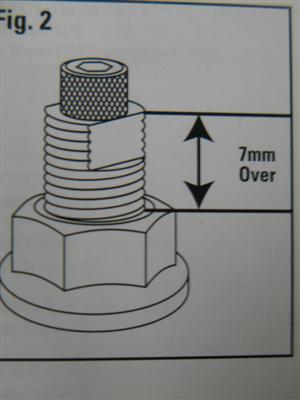

Taking a measurement of the same area which protrudes out from the mount, measuring from the edge of the nut to the tip of the shaft. If the measurement is more than 7mm in length, then the EDFC would have enough space to bolt on. Any less and there would not be sufficient space for the motor.

Checking compartment space for EDFC motor

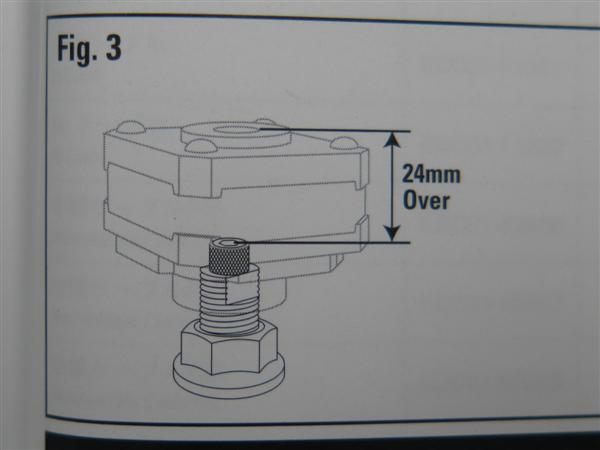

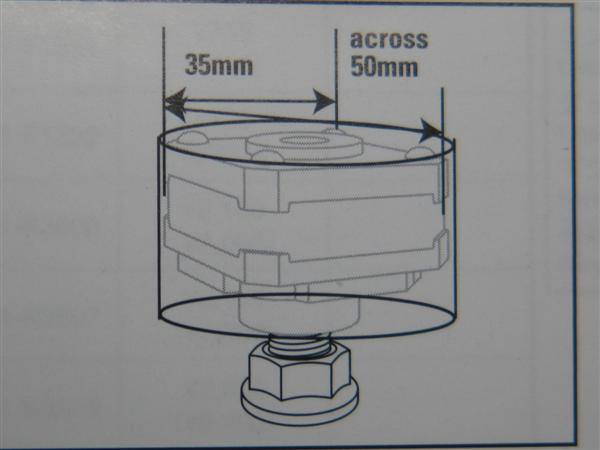

Taking a measurement from the top of the click assembly a vertical measurement of over 24mm as well as a 50mm horizontal measurement using the center of the piston shaft as the center point. Any clearances less than those detailed would interfere with either the hood or other engine compartment components and/or interior.

Caution! When checking these areas please note that the measurements provided above are the minimum required clearances for the EDFC motor installation. Please keep in mind that depending on the mount type used on the damper kit, the motor might move vertically which may require further clearance. Modifications and/or removal of supportive device around piston shaft top, insulator and/or interior might be required to allow for fitment. EDFC, in conjunction with any tower bars/strut bars may not allow enough clearance across the piston shaft for certain applications. Installation of the EDFC on any vehicles/ dampers on which TEIN had not confirmed fitment compatibility should be done at your own discretion. TEIN assumes no responsibility for any damaged and warranty void for such installations.

Always exercise caution when trying to install the EDFC units on your application whether the kit has been confirmed for fitment or the guide detailed above is being used to determine fitment. Uncertain of the installation? You can always take a look back at an early post for the EDFC installation for help.