Normally, I’d make fun of dudes wearing Emo jeans. But in retrospect, they’re probably very effective in preventing the wearer spend money, since they’ll have a hard time accessing money in their pockets because their pants are too tight. So haha on them and on me!

I bring this up because we are faced with yet another recession. Sucks to hear, I’m sure. However, it’s a serious matter for so many of us that have doubts of our job security, or in transition into a new career, or live paycheck to paycheck. You should think thrice before spending your hard-earned money.

But a recession can’t prevent all of us from having fun, right? Well, not so fast there, bud. I may have some cash in my pocket, but that doesn’t mean I can spend money like a mad man. It’s time to be smart with my money, put some cash aside for that rainy day. It’s better to be safe than sorry. And I don’t know about you, but being in debt is no longer for the elitist. It’s a club most American’s are a part of. Bigger than FaceBook. FACEDBook, is more like it.

However, if you are a penny pincher, you can always find ways to have fun on the cheap. Who says you always have to buy new? Who says expensive is always better? There are a lot of great pre-owned cars out there at very affordable prices. Some of you already have a great car to build upon, but you don’t even know it.

I like breezing through Craigslist for cheap cars that have great performance potential. How about a ’91 Civic Si for $3000? All stock, clean title, clean interior, and 117k miles (LOW for its age, if it’s the original motor), and Red! Ahhhh, takes me back to my high school days. Nice buy if you ask me! Still has A/C, a tape deck and TWO (count ’em) speakers! Wawaweewahhh!! Good deal.

Assuming you buy this car in good condition, and had another 3 grand put aside for mods, you’d have yourself a nice daily driver/beginner’s track tool.

Let’s see what mods are available during my work,,, uh, I mean, research hours.

949 Racing’s durable 15×8 6UL wheels are affordable at $159/ea.

You can get a nice set of 225/45/15’s mounted on them for around $450.

TEIN’s SS-P’s are a nice coilover package for a start in road racing, while still having more than enough compliance for daily commuting.

DSA36-2USS1, msrp $1390

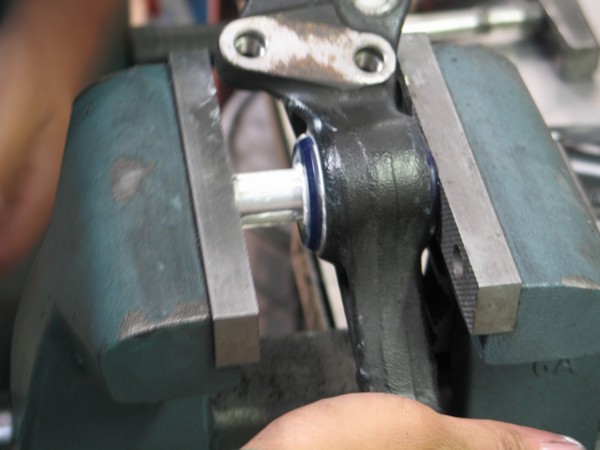

So that’s about $2,476 spent. With another $524, I can change out a few bushings. The rear trailing arm bushing goes out pretty quick. Super Pro makes one, part number SPF0807K for $113.

Super Street magazine’s project EF. The car came to us with the bushing already ripped completely out.

With the new SuperPro bushing installed = no more slop or wandering rear end.

They also have some sway bar mount bushings (front- SPF1528-__*K *different inside diameters available $27, rear-SPF1532-__*K *different inside diameters available $21). You’d still have enough money to do other bushings, but the aforementioned tend to wear early. I’d probably apply that extra money into a nice set of brake pads, brake fluid, and maybe change rotors, unless resurfacing them is good enough. Then a simple oil change and coolant flush, followed by a basic check up on spark and timing would complete it for me.

Not a bad way to start, if Honda’s are your thing. This car is a great platform to build upon, and with the coilovers, you’ll be able to experiment with different spring rates. You can also get the dampers revalved if you want to try much stiffer springs. Beyond that, engines of similar size or even a B-Series, and now K-Series motor, can be swapped in. But hey, let’s keep it simple for now. With this setup, you’ll be,,,,,,,, well,, you’ll be slow. But with a low power motor, you can improve on other skills, such as learning to maintain your momentum through turns, or establish your vehicle’s limitations, as well as build up your track skills and memory. From there, sky’s the limit. Budget’s the limit, too. You can be the next Stig (look at the above Civic pic for motivation)!

So, not to fear, those of you with limited budgets. Be good with your money, or face some serious financial woes. Be a wise saver and shopper. Research before you buy, and don’t by crap! Some of you may be able to score these parts mentioned as used goods! Dunno about the bushings, though.

Take it easy, guys and girls and happy tuning!