We’re constantly thinking of ways to improve our products. More importantly, we’ve been working towards making our coilover kits more affordable to match a customer’s budget, but also bring new innovations that we’ve pioneered through our involvement in motorsports.

Available in Spring of 2015, we’re reintroducing our STREET FLEX line into two new lines- the FLEX A and FLEX Z.

Starting with the FLEX Z line, we will bring a new affordably priced version of our STREET FLEX coilovers. How affordable? MSRP will start from $800!!!

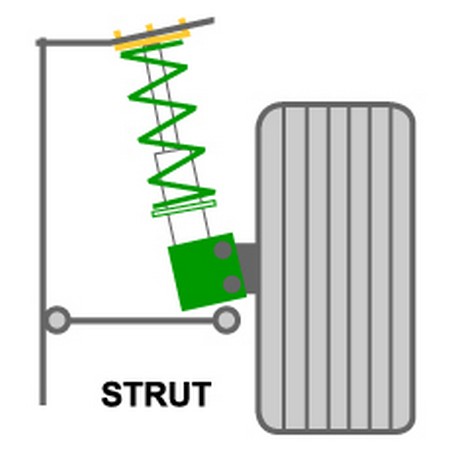

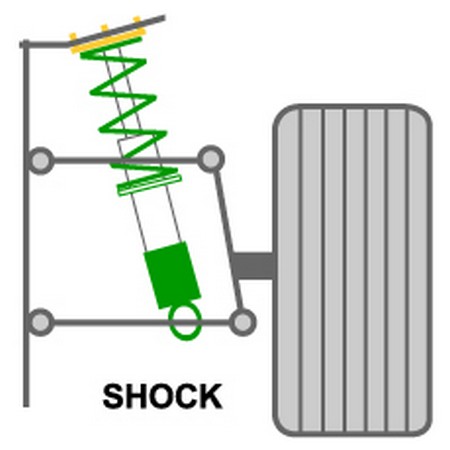

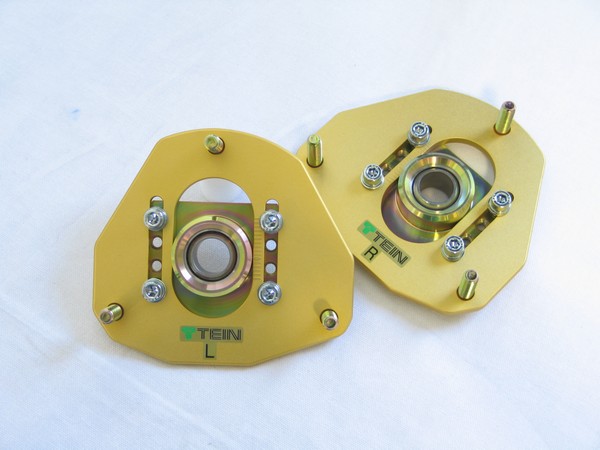

Features-wise, not much is different from the current STREET FLEX. It will still include full-length ride height adjustment for separate spring preload and height settings, upper mounts (camber adjustable for most MacPherson struts), 16-way damping force adjustment using our ADVANCE NEEDLE technology which provides a much wider range of damping force adjustment per click (~ 200% increase in damping force adjustment range over our previous needle design), EDFC series compatibility, and our proprietary coatings (ZT coated damper bodies, and our 2-layer/1-bake powdercoating for lower brackets and upper mounts). We were able to bring cost down on the new FLEX Z dampers by making them fully sealed units (non-rebuildable).

The biggest benefit to a fully sealed non-rebuildable damper, other than the extremely affordable price, is that the customer will have a maintenance free damper (we still recommend to periodically inspect external components such as seat locks and spring seats, dust boots, and bump stops). Instead of rebuilding their damper, or if they have a blown damper several years down the line, they can purchase a replacement single damper. This translates into less downtime for our customer, who most likely needs to get their car back on the road.

That’s not to say that we’re not proud of our overhaul/revalve service. In fact, we will continue to provide that for older coilover models and for some upcoming, such as the FLEX A.

The FLEX A coilovers will carry the same features as FLEX Z but will be rebuildable, much like the current line of STREET FLEX. We will also include a newly developed feature, our Hydraulic Bump Stop (H.B.S.). Technically it is not a new feature. Instead it is a much more affordable and effective version of the Hydraulic Bump Stop we use on our GROUP N dampers used in rally racing.

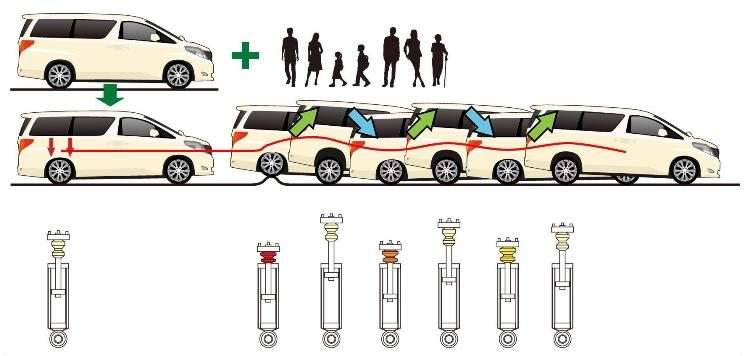

How does our HYDRAULIC BUMP STOP work?

As the damper reaches/nears full compression, there is a spring that the piston makes contact with. This helps to build up pressure closer to the base valve. As pressure continues to build around the base valve, a secondary spring will compress, which allows a cup shaped washer to seal most of the orifices around the base valve. This effectively restricts damper fluid flow, increasing this pressure and slowing down the piston’s speed. Finally, as the damper approaches full compression, a third spring will compress allowing a needle washer to open and allow damper fluid to pass through this single orifice. In all, the way our HYDRAULIC BUMP STOP works is by gradually increasing pressure during compression. While mainly based on piston speed (high-speed compression), the unit will work even as the damper nears full compression.

This means that the damper will not fully bottom out. The effect on ride quality is that it will not be as harsh during rebound, much like would be the case with a longer polyurethane bump stop. Why is that? A polyurethane bump stop is compressible. However, it acts as a much stiffer spring, which the damper isn’t necessarily valved properly to control. This means that rebound force is much greater, and that can also translate into uncomfortable oscillation (where the vehicle feels very floaty). With our H.B.S. the rebound rate is not affected, and the vehicle can return to it’s 1g (vehicle weight on the ground) ride height in a smoother fashion.

If you’ve ever watched videos of off-road race prepared trucks with very long stroke suspension, which use another form of hydraulic bump stop (typically mounted externally from the damper), watch what happens after a huge jump. The vehicle lands back down, suspension squatted nearly all the way down. However, when the suspension rebounds and the vehicle returns to it’s 1g ride height, it just settles. No crazy up and down movement. In other words, there is no wasted vehicle body movement. The driver can continue driving full throttle after a jump. Pretty impressive!

That may be a bit of an exaggeration of what our H.B.S. does for a street car (unless you compare it to our aforementioned Group N dampers, which go on production vehicles), however it is the same effect, just in a smaller package and for a shorter damper stroke.

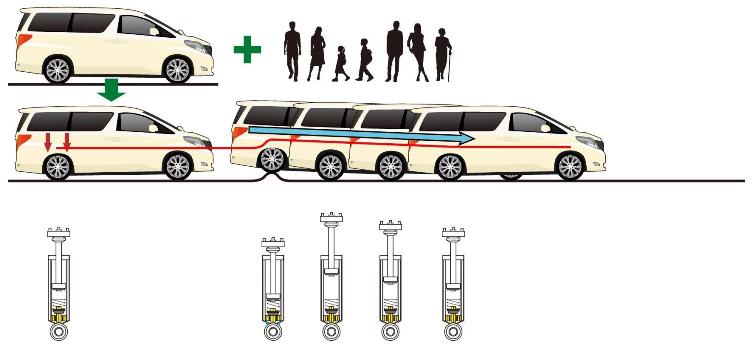

Our HYDRAULIC BUMP STOP works extremely well on suspensions with longer stroke, such as luxury sedans or mini vans. While still effective and beneficial in applications with shorter damper stroke, it isn’t as noticeable in feel.

The new FLEX A coilovers will start at $1350 for a complete set!

Look out for these new products by mid April 2015!!!