Tein Blog Readers,

I introduce to you my 2010 Mitsubishi Lancer Evolution X.

I chose the Evo X because I believe it has the perfect balance between daily driver and track car.

For your everyday needs it has 4 doors, it seats 5, and has a decently sized trunk.

When you get to the track it’s 2.0L Turbo Charged S-AWC System makes for a very fun time.

New off of the lot this is what I had to work with:

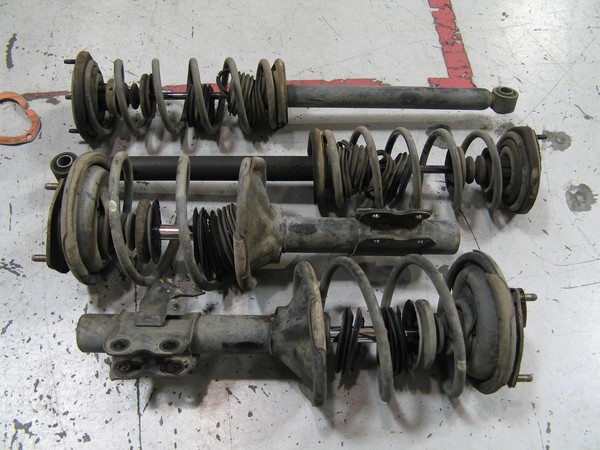

Having switched from a nearly 2 decade old BMW that was still running the suspension that was installed at the factory, the ride quality of the Evo’s stock suspension was a difference of night and day for me. But I still wanted more out of my car. Not to mention the stock ride height, it may be acceptable if the car was going to see any time on gravel; but my car was destined to be a tarmac queen, it needed to be lowered.

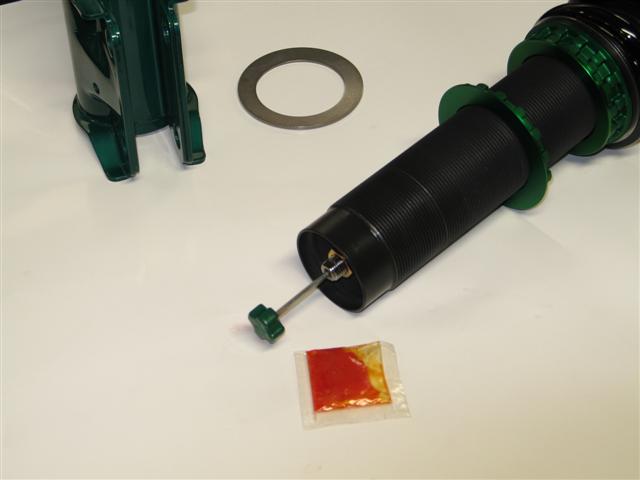

When it came time for me to choose one of the many suspension products we offer for the Evo X the decision was quick. Right at the time that I purchased my Evo, Elliot’s TEIN Sponsored EVO X was being returned to stock form, so all I needed to do was remove the suspension from his car and install it onto mine. Having done the majority of the track support for Elliot’s car I knew the suspension and setup well enough to be confident that my car would have no problems with said suspension installed.

Front Dampers installed and EDFC Wiring being taped up:

I even switched out my stock brakes for Elliot’s APM Rotors and Project Mu Pads:

In order to route the EDFC Wiring and mount the Controller I had to tear apart my brand new interior:

After having worked through the night transferring over many more parts I later took my car to Evasive Motorsports for a track ready alignment.

On the streets the Mono Flex Dampers provided just the right amount of comfort and control. The ride height was also right where I wanted it, not too low, not too high:

Using Mono Flex Dampers and upgraded brakes I was able to push out a 2:20 on Buttonwillow’s Time Attack configuration: