Never before has a consumer stepped foot into the TEIN factory, ever!

As you can imagine, TEIN (as with many other manufacturers) has some proprietary methods for manufacturing shock absorbers, with several processes pioneered in-house. In fact, there are some machines developed specifically by TEIN engineers solely for our own use. So, to show that to the public may be detrimental to us since we do not want such information to be released to the public. This is information that can reach another suspension manufacturer!!!

However, there is a benefit to showing consumers what TEIN does and what we’re capable of. For one, it’s a sign that TEIN is confident in our technology. Second, consumers are just as interested in seeing how their products are made. So why not show them?!

Well, that’s exactly what we did! We worked with DSPORT magazine to arrange a tour of our facility during their Tokyo Auto Salon guest tour for this year.

Every year, DSPORT Magazine arranges a tour package for interested people. For about $3,500/person, guests get to take a trip to Japan and visit Tokyo Auto Salon and several Japanese performance parts manufacturers’ facilities. So it sounded like a prime opportunity to have TEIN show the public our factory.

We felt bad for our guests, though. The day before was to be a trip to Fuji Speedway. But, due to bad weather the event was canceled. We were hoping our tour would make up for that missed event!

We had just over 40 guests for our tour on January 19th.

Prior to the tour, we gave our visitors a general overview of our property, including our offices, R&D facilities, Quality Assurance facility, and manufacturing.

Since it was a fairly large group for us, we had split up the group among 8 tour guides.

Below are a few pics of the factory’s facilities and processes. Again, we have to limit what we can show the public. Sorry:

Other than steel components, we also use aluminum alloys. We stock three grades of aluminum billets, each one to be used depending on the application and use. For aluminum damper shell cases, we use an A 7050 grade extruded tube, however.

A sampling of some of the suspension components our lathes can process, from prototype to finished product.

Some of our components are machined from billet blanks, which we cut from larger bar stock, using various grades of steel and aluminum depending on the product requirements. These steel pucks will end up becoming our pillowball cases for strut type upper mounts.

We use tubing of various sizes to make damper shell cases to lower brackets for full-length adjustable dampers.

Lower brackets, after any necessary welding, go through shot blasting prior to any surface coatings.

Semi finished piston rods that have just been gun drilled (for damping adjustable suspension applications). Still a few more steps to being completed sub assemblies.

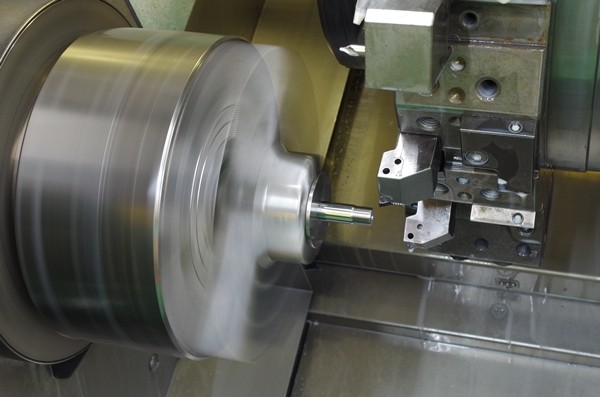

We have many lathes to handle different processes, such as piston rod machining. Here, threads being cut for piston valve assembly.

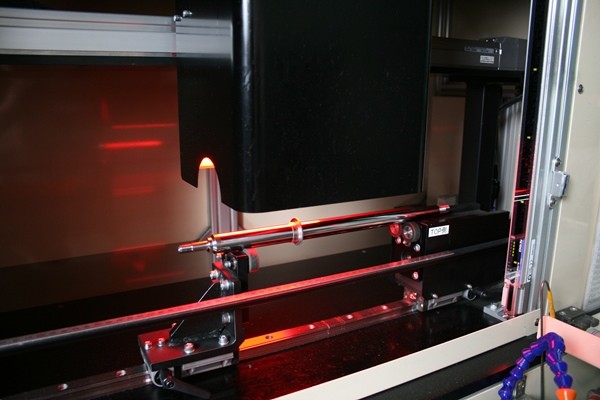

Vital for our piston shafts is our high-resolution inspection machine. It is capable of detecting even the slightest flaw on the piston shaft surface. Each and every piston shaft is inspected. If defects are found, we must discard the shaft.

Our Swiss Precision Lathes help create small damper components like our ADJ Needles. Such small parts require great detail, which this machine can do consistently. It also runs nearly non-stop!!!

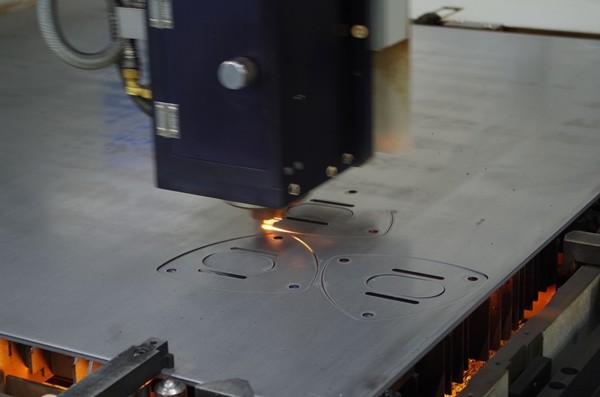

A recent addition to our factory is this Laser Cutting Machine, capable of cutting steel up to 16mm thick using a carbon dioxide laser beam. Quite a fast and efficient process!

Here’s the Laser Cutter in action, cutting our camber plates for strut type pillowball upper mounts.

The second floor of our factory handles our surface coating stages. First, we shot blast our steel components. This allows our powdercoatings to adhere better to the steel bodies.

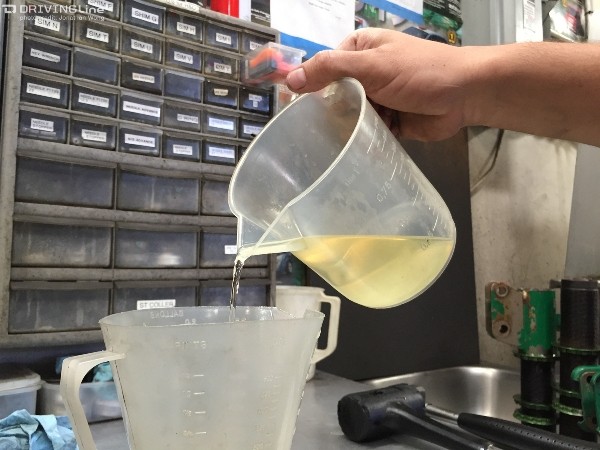

After shot blasting, some shell cases go through our patented 2-Layer/1-Bake powder coating process, where zinc powder is first applied, followed by our trademark green powder paint, then cured.

While a couple groups went out for the factory tour, we also set up a test drive so visitors can try our new FLEX A dampers and EDFC ACTIVE PRO on a Toyota Vellfire.

The tour went faster than expected, and considering the factory was in full swing when we had it, it was difficult to hang around the machinery for very long with TEIN staff trying to navigate around us.. We even had to speed through some demonstrations by factory staff. Fortunately we were able to showcase a lot of our machinery and even some prototypes.

Afterwards, we took our guests out for a sushi lunch.

Overall, it looked to be a fun experience for our guests. I got to speak with several of them and they were all impressed with our manufacturing. So many people wanted to purchase TEIN suspension kits right away!!! Lol. I felt bad that we couldn’t arrange any suspension purchases while we were there, but I’ll be taking care of them on their return to the U.S.!

We hope to continue doing tours for guests each year. So, if you plan on making your way to Tokyo Auto Salon, take a little extra time from your trip to stop by TEIN!!!……

……..Like our friends at Evasive Motorsports!

Thanks for stopping by, guys!!!!