Whenever we hear that (blog title), we tend to understand that a customer has a set of our lowering springs. However, for some strange reason, people online or that call us are referring to our suspension kits as coils, whether it be a complete suspension kit like a STREET FLEX or STREET BASIS, even a SUPER RACING setup.

We must ask- WHY ARE YOU REFERRING TO THEM AS “COILS”?!

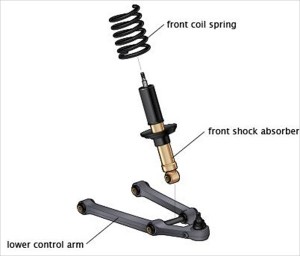

We’re just as guilty, using different terminology than what some people may understand. For example, saying “coilover” implies simply that- a coil over a damper. This is how most people know of our product since our height adjustable setups are typically coilover, but is this a coilover?:

As pictured above, this “coilover” kit uses our Height Adjust System (H.A.S.) for the rear, as pictured on the left. So it is in fact not a “coilover” with exception of the fronts (pictured on the right). We’re wrong for ever referring to such kits as a coilover package. Instead, this is a suspension kit. But, for simplicity’s sake, and in acknowledging what are customers know us for, we continue to call them coilovers. It’s easy, and it won’t confuse our customers.

There are other things/terminology we may use that may be either incorrect to some, or just named differently. For example, the name “Shock Absorber”. It is in fact a “Damper”. Shock Absorber is incorrect because it isn’t absorbing shock. What it is doing is turning kinetic energy (the up and down motion of the vehicle and unsprung mass) and converting it into thermal (heat) energy. Nothing is really being absorbed. It is a transfer of energy from one form to another. However, most people understand them to be Shock Absorbers, so we just roll with it.

And yes, it is “Damper” and not “Dampener”. They may share some similarities in meaning, but they’re in fact used differently. Dampener is typically used to describe a wet or moist condition. But it can also be used to describe a deadening or depressing. Damper, on the other hand, is mainly used to describe a reduction in oscillation or amplitude of force.

We also hear people ask for “Pillar Ball Mounts”, which is easily understood to be (how we know it) Pillowball Mounts. Not a big deal.

Another one that we hear is when people refer to our Seat Locks and Spring Seats (where you can adjust a spring’s setting and vehicle ride height) simply as “rings”. Sometimes we hear them being called “collars”. We use collars, but they are usually much smaller and are used as a spacer in our upper mount assemblies.

That’s another one- upper mounts being referred to as “top hats”. Not really a big deal, and some upper mounts kind of look like top hats. So, [top] hats off to you for using that description!

There are some less obvious things that we cannot fault a person for. For example, our inverted dampers for strut type monotube setups, like our older MONO FLEX and our SUPER RACING. People will refer to the shiny part of the damper assembly as the piston or piston shaft. Again, although that is incorrect, we cannot fault the customer for that. Since the damper is inverted, the whole assembly is upside down. The piston shaft is now on the bottom side and inside of the threaded shell case.

In the above picture, the shiny rod coming out of the threaded shell case (black) is in fact the damper body and not the piston shaft. The piston shaft is itself inside the threaded shell case and completely out of view.

There’s also the use of the name “Serration Bolts” which we use for the studs in our upper mounts (that secure the upper mount assembly into the strut or shock tower). We realize that confuses a lot of people when they need replacements of these components. Sorry!

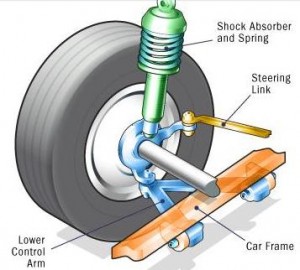

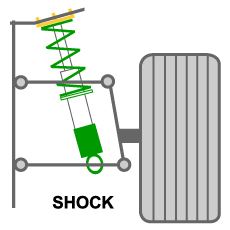

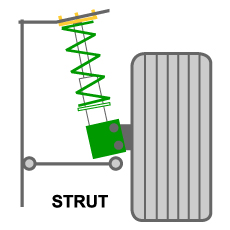

The use of “Strut” may also be confusing for some. The above picture of the MONO FLEX for Subaru WRX shows struts, which this chassis of Subaru uses for front and rear. When we say strut, we’re referring to the MacPherson Strut design, which other than being a damper, also serves as a structural member of the suspension by supporting the knuckle assembly. The knuckle assembly comprises of the wheel and brake components. Struts have to be a bit larger in size and be able to handle large side forces/loads.

In comparison, a “SA” type of damper (short for “Shock Absorber”), which is used in Double Wishbone or Multi-link type suspensions, doesn’t have to support such side loads. They are used strictly to control vehicle motion. This is also why we don’t make camber adjustable upper mounts for our SA dampers. It’s position or angle will have no affect on wheel camber.

Can you see the difference between these two suspension designs?

Can you see the difference between these two suspension designs?

For sure there are other things we hear from customers, but this covers a majority of terminology we hear.

Hopefully that helps break down some of our terminology for suspension components!

![black friday list page[1]](http://teinusa-blog.com/wp-content/uploads/2013/11/black-friday-list-page1.jpg)

![black friday list page[2]](http://teinusa-blog.com/wp-content/uploads/2013/11/black-friday-list-page2.jpg)