We’ve had this question several times before, and it’s a pretty good question for us. It tends to go without explanation in magazines. Instead, you get an article on a car build and see a shiny can sitting in an engine bay that you’d love to have. But, what is a catch can there for?

The main purpose of the oil catch can (sometimes referred to as a Catch Tank or Air/Oil Separator) is to collect oil and carbon sludge that comes from the combustion cycles your engines go through. It’s not that the vehicle manufacturer’s are not aware of this issue. In fact, many cars already have a form of recirculating these blow-by gases from the cylinder head and crankcase PCV (Positive Crankcase Ventilation) valve.

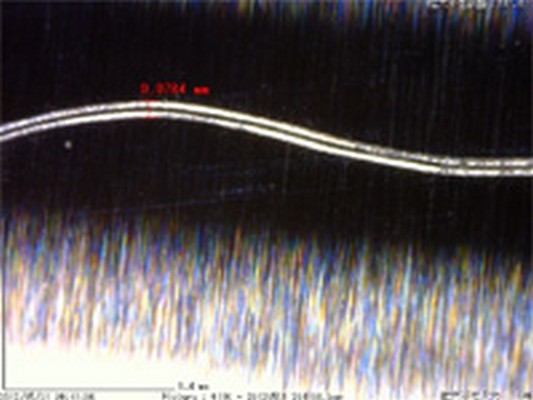

Blow-by gases are harmful to the engine in many ways. The combustion chamber isn’t perfectly sealed. Whether its the rings around the piston, or the valve guides in the cylinder head, there is still a chance that the gases coming from the combustion cycle will escape elsewhere other than the exhaust system.

Recirculation of blow-by gas is done to help reduce emissions. Back in the day, and still common among the hot rodders, valve covers were vented with an awesome looking filter (basically a mini conical or cylindrical intake filter). This allowed the blow-by pressure to vent freely into the atmosphere. But, as has been a concern since the introduction of the catalytic converter in cars these days, we’re trying to reduce the output of harmful gases that affect our air quality.

By being able to recirculate the gases, it has a chance to go through the combustion process once more to be burnt completely and pass through the the exhaust as it is intended.

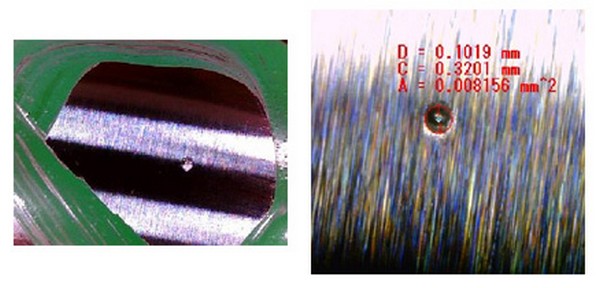

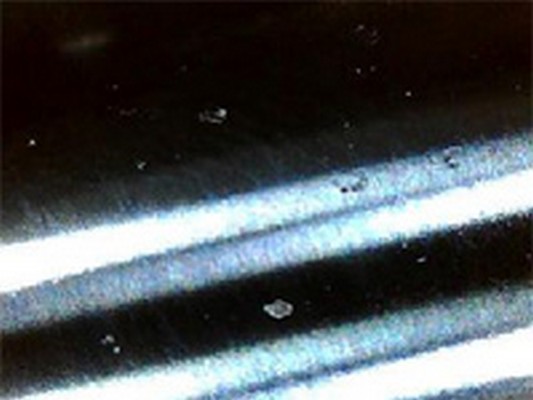

The problem is that not only gases get recirculated. Oil and carbon sludge also gets recirculated. And while that may seem to be okay, this can leave a nasty residue in your intake system, all the way through the intake manifold. Also, the recirculation of the oil and carbon sludge can reduce your engine’s power output and performance.

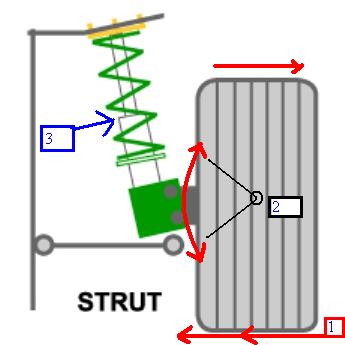

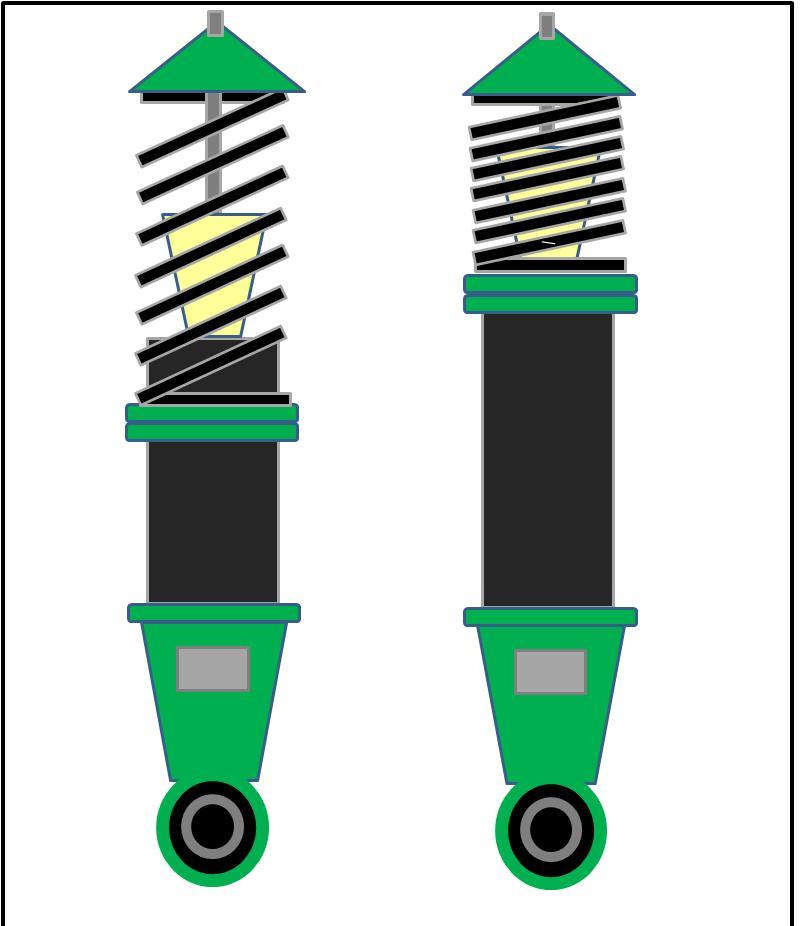

So, adding a catch can into this recirculating system helps by allowing the heavier oil and carbon sludge to fall into the can, while the lighter gases can continue their flow through the intake system. *Yes, that means the catch can must be oriented in a specific way to be able to trap oil/carbon. Basically, tilting the can at an angle, or positioning it sideways will not effectively trap the oil/carbon, especially if there is a lot to be collected.

Do all cars need an oil catch can? Not really. Although every gas powered means of transportation experiences gas blow-by, not all cars have it so badly. However, engines that experience high combustion pressure are more likely to suffer. Turbocharged vehicles also may exhibit more blow-by. So an advanced system to trap the oil and carbon sludge is a good idea, if the car doesn’t already have one. Track cars benefit from catch cans because they constantly see high rpm engine loading, easily increasing the amount of blow-by.

It must also be noted that the reason one end of the recirculating system connects to the intake side is that the vacuum created by the intake cycle helps to pull in the gases more effectively. Make note of that, turbocharged or supercharged car owners. We once had an instance where a customer hooked up one of our Carbing Oil Catch Cans to his supercharged Acura RSX. One end of the system was hooked up properly to the port on the valve cover, while the other end was hooked up to the intake manifold, after the supercharger. That is the incorrect method. You see, if the cylinder head will experience pressure build up, that means pressurized gases are escaping through the valve cover, where a port is already fitted. If you hook the other end up to the the pressurized side of the intake manifold, where boosted air enters, you basically are pressurizing the catch tank from both ends, which does nothing to catch oil and carbon. Although having a supercharger or turbocharger doesn’t mean that highly pressurized air is constantly being fed into the engine (partial throttle, off-throttle coasting), it can be disastrous to the recirculating system if both ends are pressurized.

Again, one end must be pressure fed, while the other is vacuum fed for the system to work properly.

Carbing’s Catch Can is designed to hook up to the factory recirculation system. So, no major modifications are required to install this item, since it replaces one line and links the catch can in between to trap the oil and carbon sludge.

A nice feature of the Carbing Catch Can is that it also has a clear tube gauge to show how full the can is. This comes in handy if you know how often you’re emptying out the can. If you haven’t changed your driving style much, but have to empty the can a bit more frequently, it may mean that you are experiencing some other engine problems. So, it’s a nice safety measure.

For more information on the Carbing Catch Cans, please check out the following link

Carbing.co.jp

TEIN.com

And of course, if you are interested in getting one for your car, but need to find out which size you need, please don’t hesitate to contact us!