I’d like to approach this topic by first stating that racing harnesses are not suitable for daily driving. When used properly, a good harness system keeps you relatively firm in place, minimizing your body movements critical during quick maneuvers on track. The idea is to keep you planted into the car and reduce any excessive body motions that just add hysteresis to your hand and foot inputs.

With racing harnesses, proper head and neck restraint systems should also be used. Obviously, helmets are for head protection, but you should also use a neck brace (or a HANS device, if you have the money) when using a helmet and racing harness in conjunction. It would be pointless to use a harness that keeps you pretty firm in your seat while your next could pivot around in a nice axis. In a frontal impact, your neck can easily swing forward in an unsafe manner. Add the weight of the helmet you’re wearing, and that just adds to the trauma.

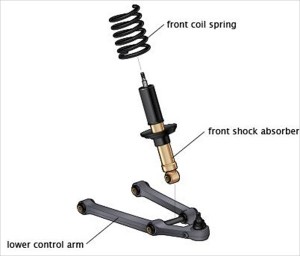

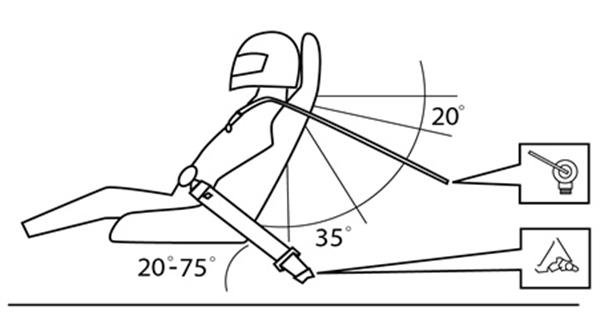

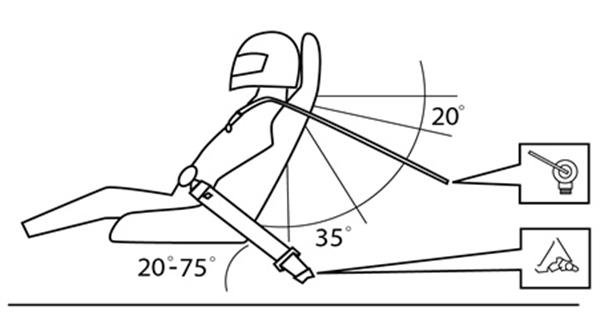

Another important notice- the angle of the racing harness must be set properly. If the shoulder straps use a very low anchoring point (like right behind your seat and towards the ground), that can cause serious bodily damage (paralysis, or even death) due to the compression of your spine in a frontal impact. Mounting or setting the angle of the shoulder straps horizontal to your shoulders (+/- 20 degrees) can help prevent that. One of the safest ways is by using a harness bar. But they aren’t available for every vehicle. So you would have to find a secure, roughly horizontal (again, +/- 20 degrees) anchoring point for the shoulder straps to secure on to.

The picture above shows the suitable angles for mounting the shoulder straps.

The use of the harness bar allows the anchoring point to be placed low behind the front seats since the bar’s angle relative to the shoulder height is horizontal. So in a frontal collision, there wouldn’t be any compressive forces pushing down on your shoulders. Instead, the harness bar would take the vertical load as your body attempts to move forward in an impact.

Harnesses mounted without a bar. Assuming the seat’s backrest can take the vertical load rather than your shoulders, and the anchoring angle set within an acceptable range, this is okay. I’d prefer a harness bar, though.

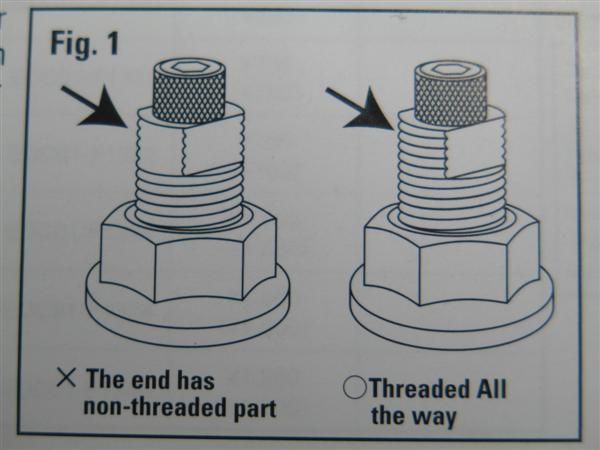

Anchoring the harness using the bolt holes from the OE mounting is more than sufficient and secure for eye ring bolts included with some harness sets like Takata.

Regarding neck support (HANS, specifically), this is just as important as you can see in these photos with & without HANS

Fortunately, I was able to find much of this necessary information on Takata Racing’s website

http://www.takataracingproducts.com/guide.html

but I also looked up some images online and pulled up some interesting information.

By now it must sound like safety equipment is a very expensive proposition. But this shouldn’t be a factor that you decide to skimp on when preparing a vehicle for racing.

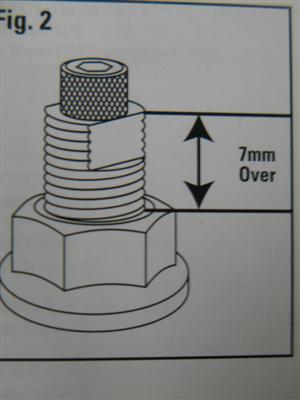

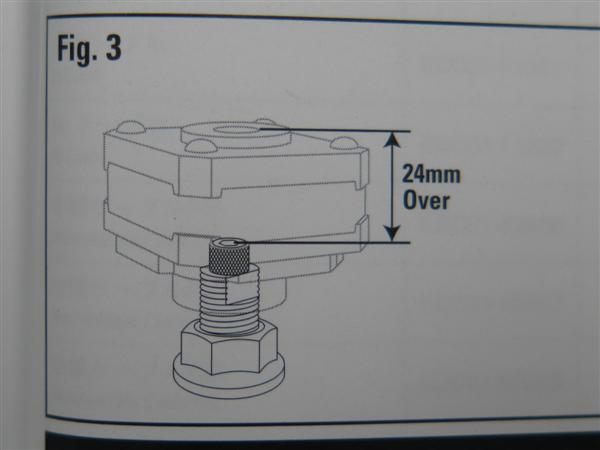

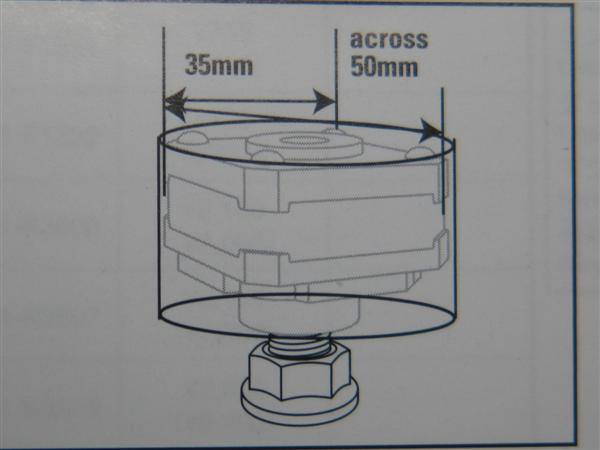

The Takata harnesses we sell include most of the necessary hardware to use factory belt mounting points. But optional longer eye bolts and mounting plates are available if you decide to make your own mounting point.

Also, if looping to a harness bar, a 3 bar adjuster will be needed. Pegasus Racing sells such adjusters from their website

https://www.pegasusautoracing.com/productdetails.asp?RecID=627

The Octane Report also did a great write up on how to install harnesses to a harness bar

http://octanereport.com/gallery-how-to-takata-safety-harness-loop

I hope this gives you some great insight on safety equipment, and what is necessary for setting it up correctly. Just remember, your safety is the most important aspect to consider.